What is the CNC construction set?

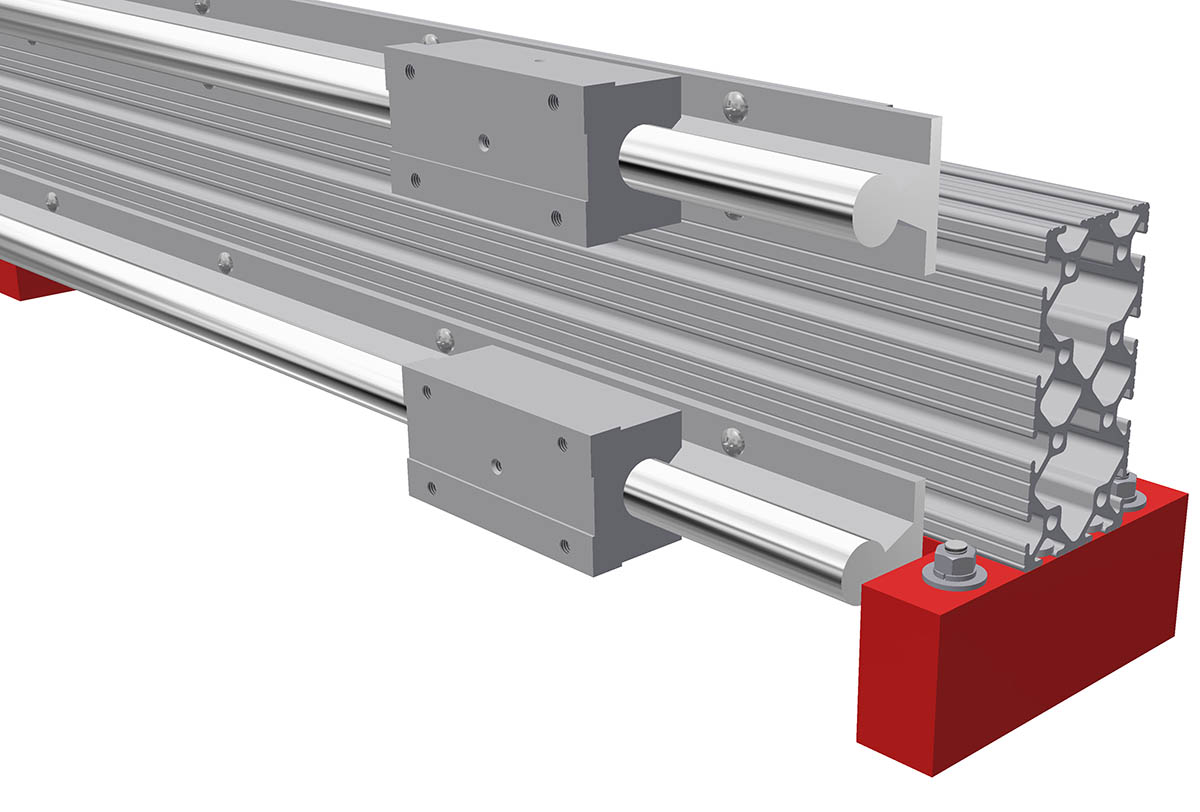

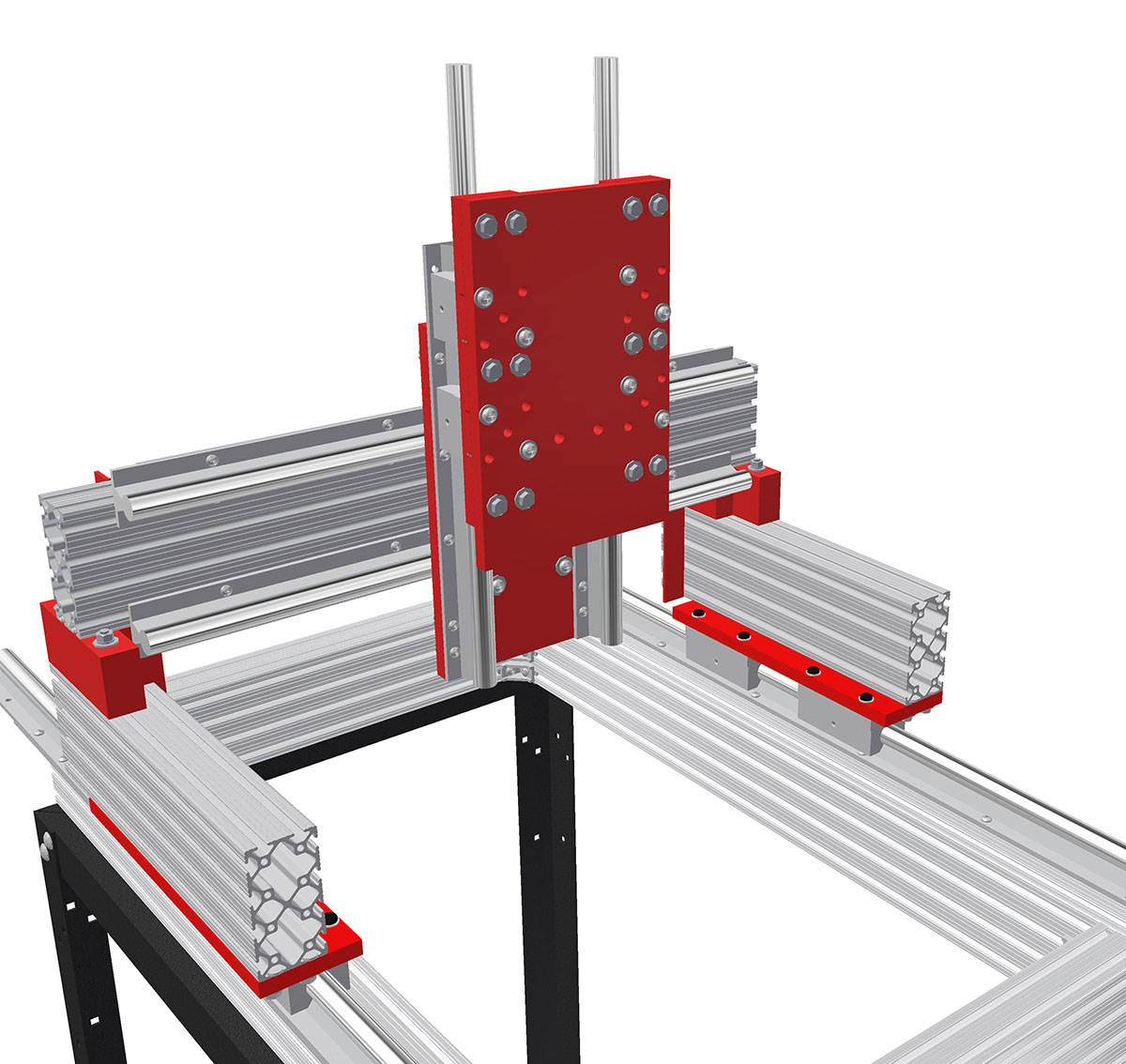

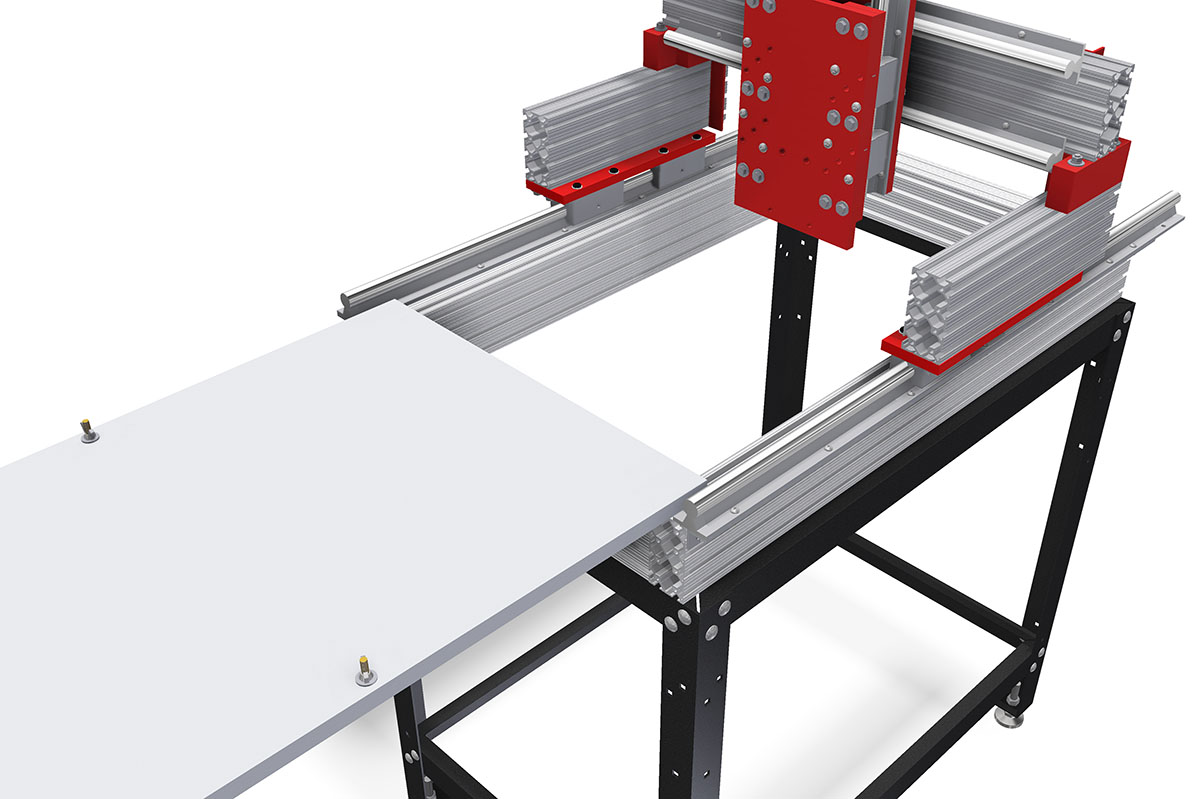

The CNC Construction Set (CNCCS) is a CNC machine with a 15" x 28" travel.

The machine is designed to accommodate various CNC operations such as:

CNC Plasma Cutter (Shown on the Left)

CNC Router or VFD controlled Spindle

CNC Laser Engraver

CNC Drag Knife

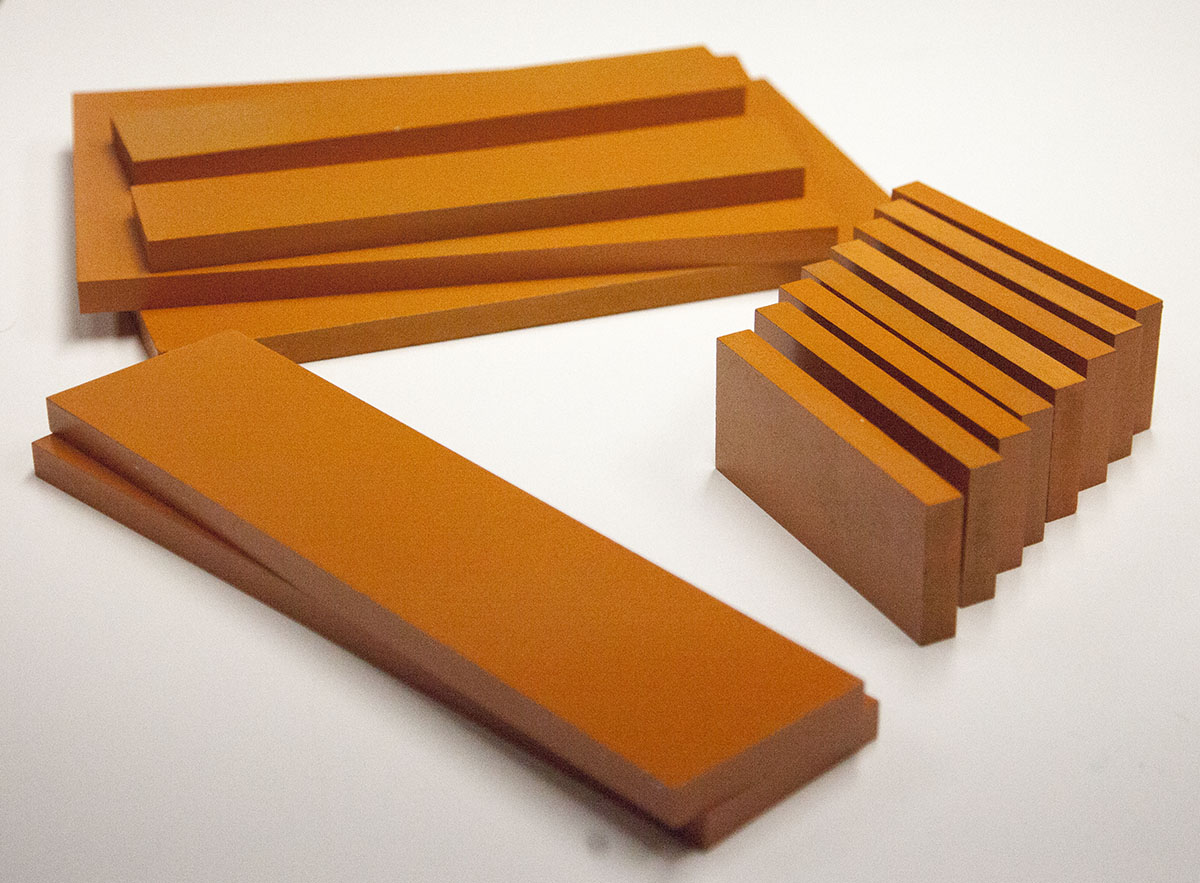

Hot Wire Foam Cutter

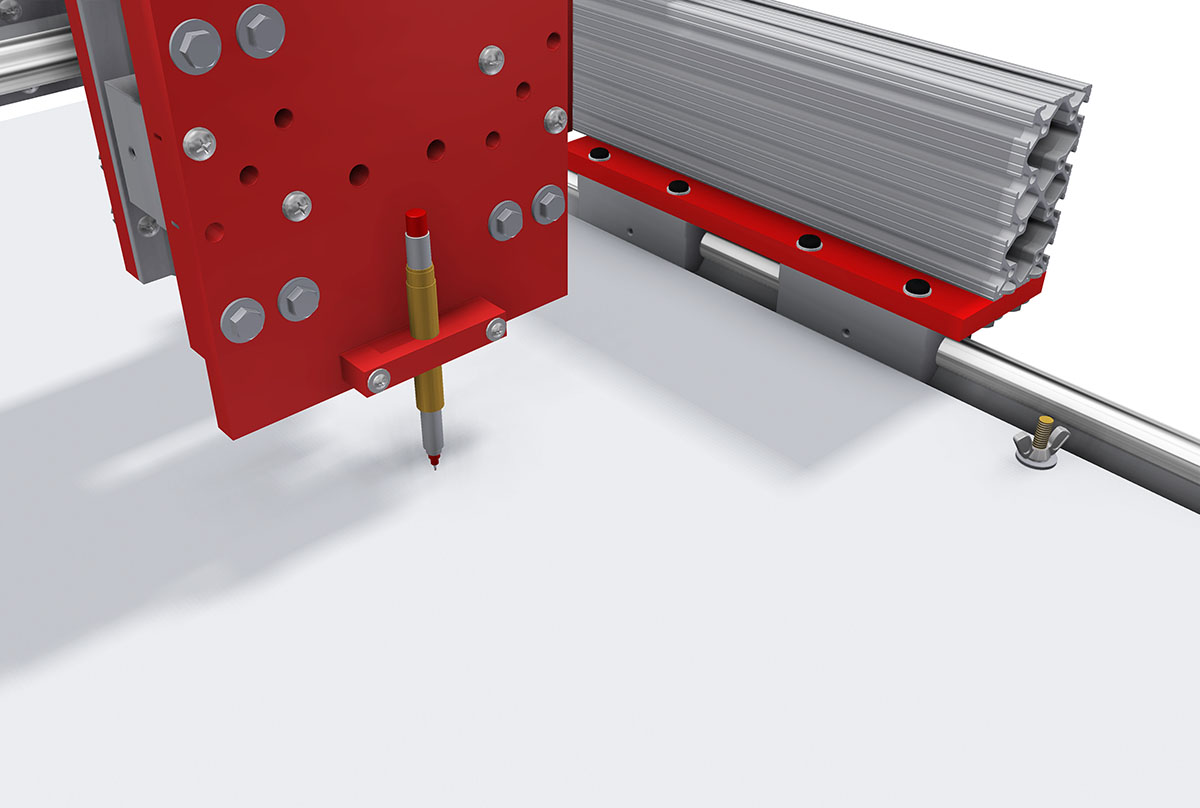

CNC Pen Plotter

CNC Plate Marker

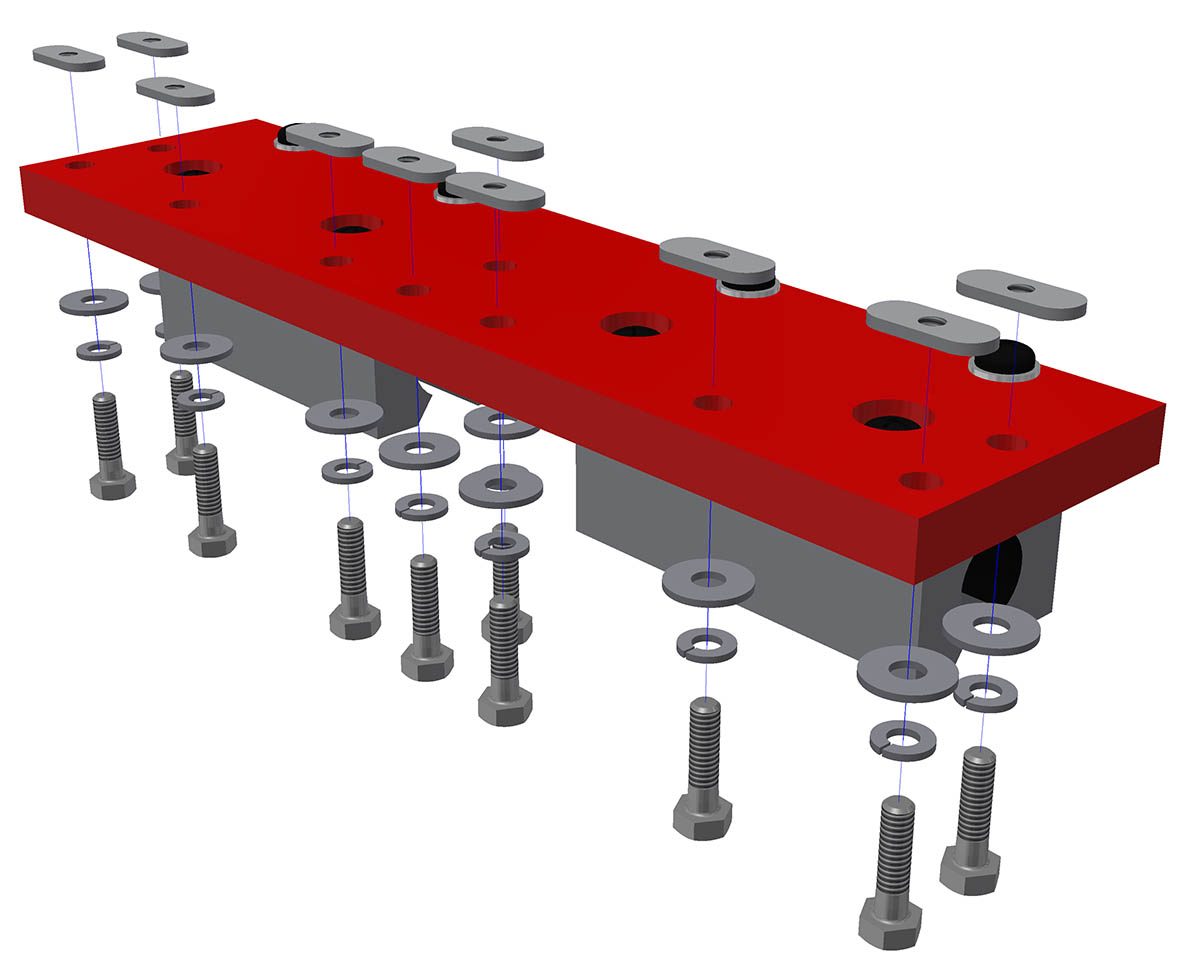

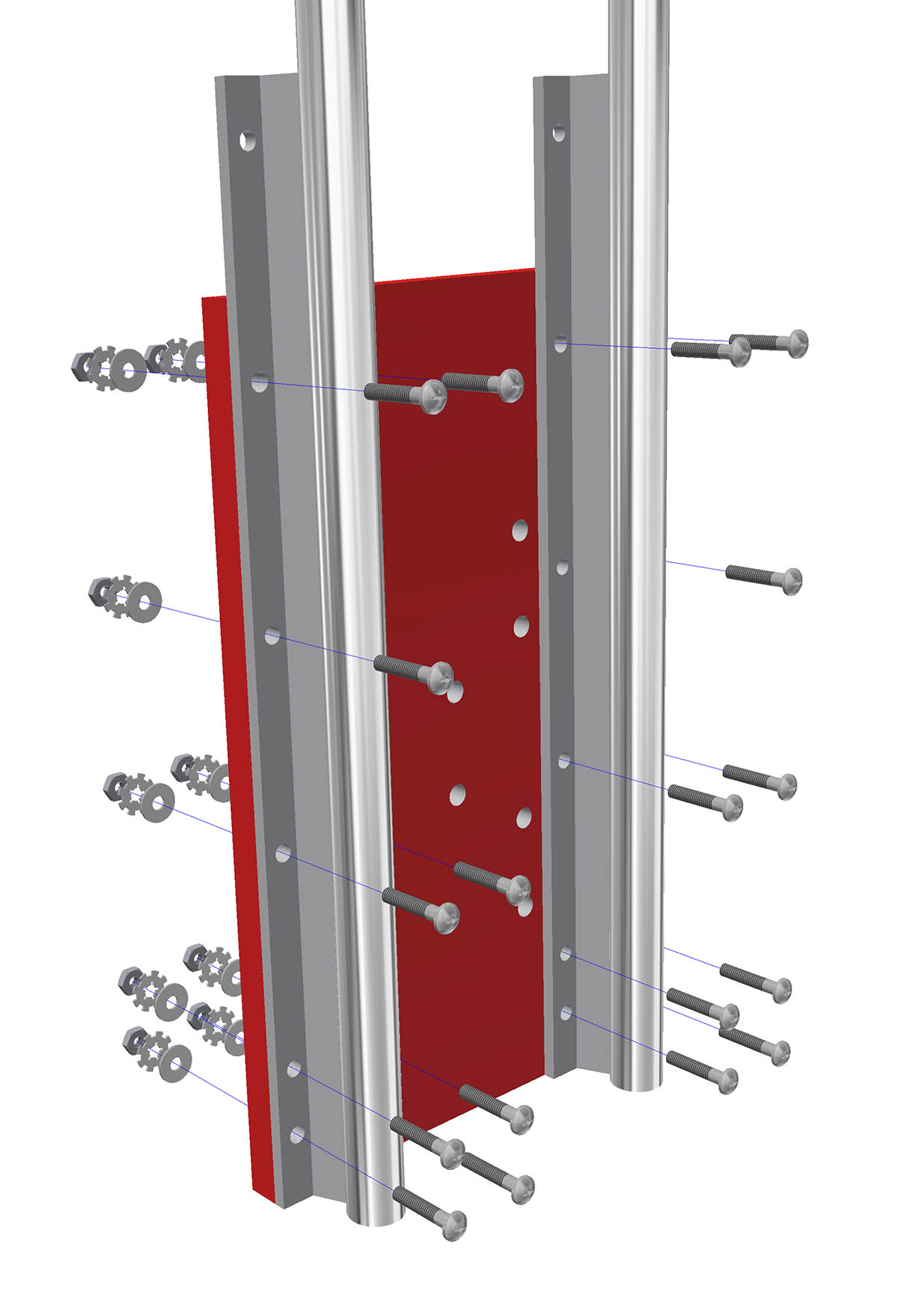

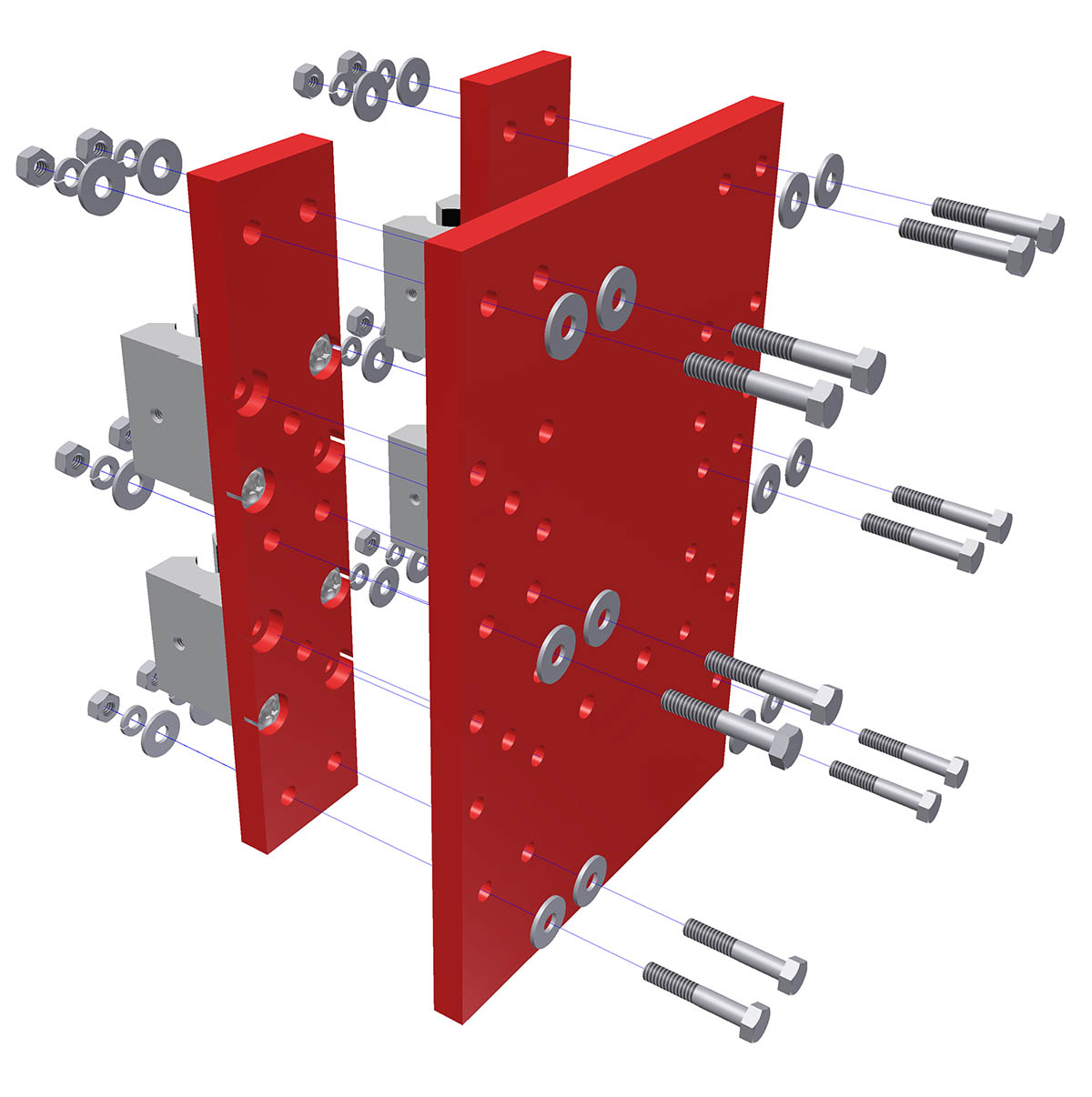

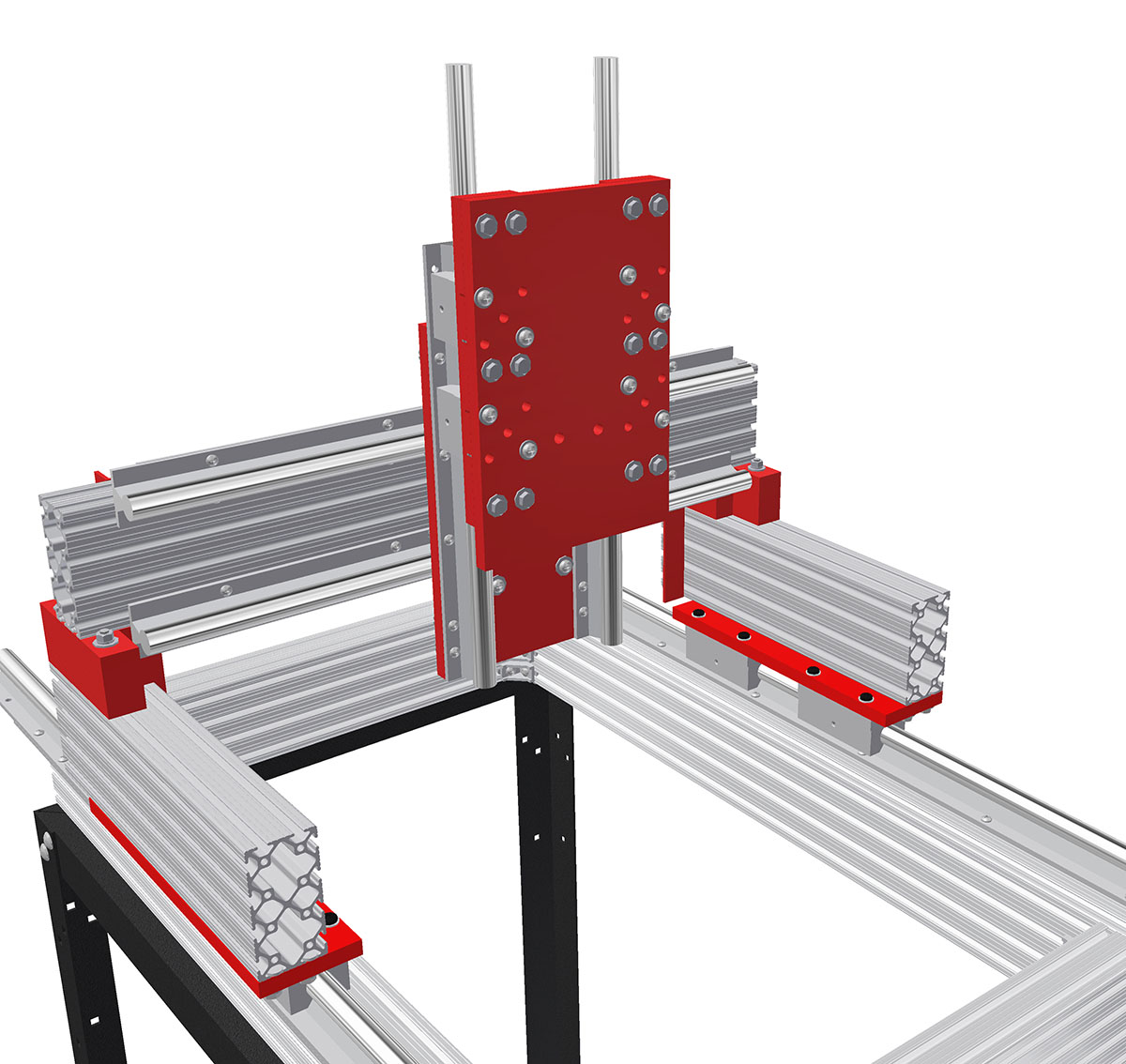

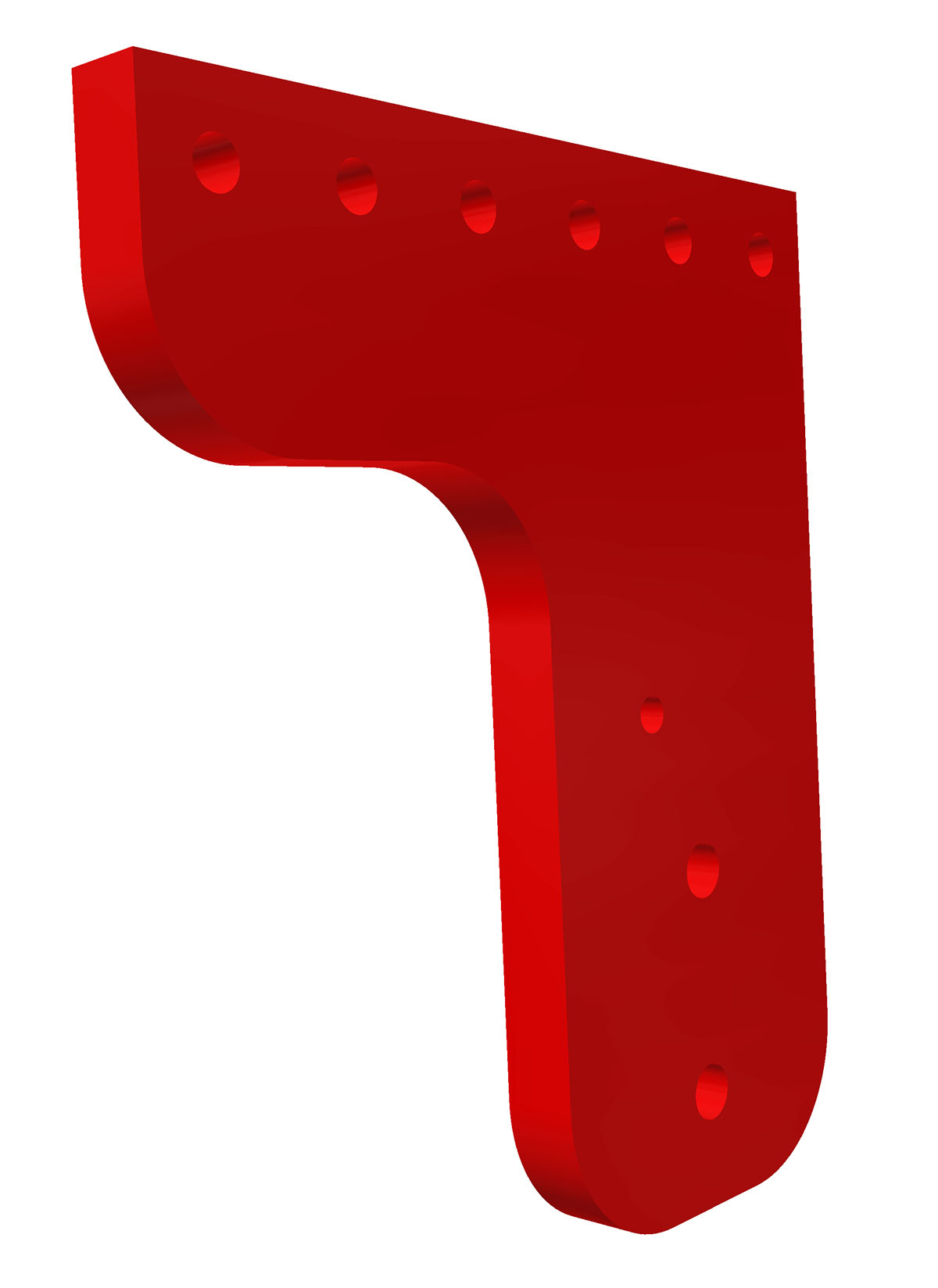

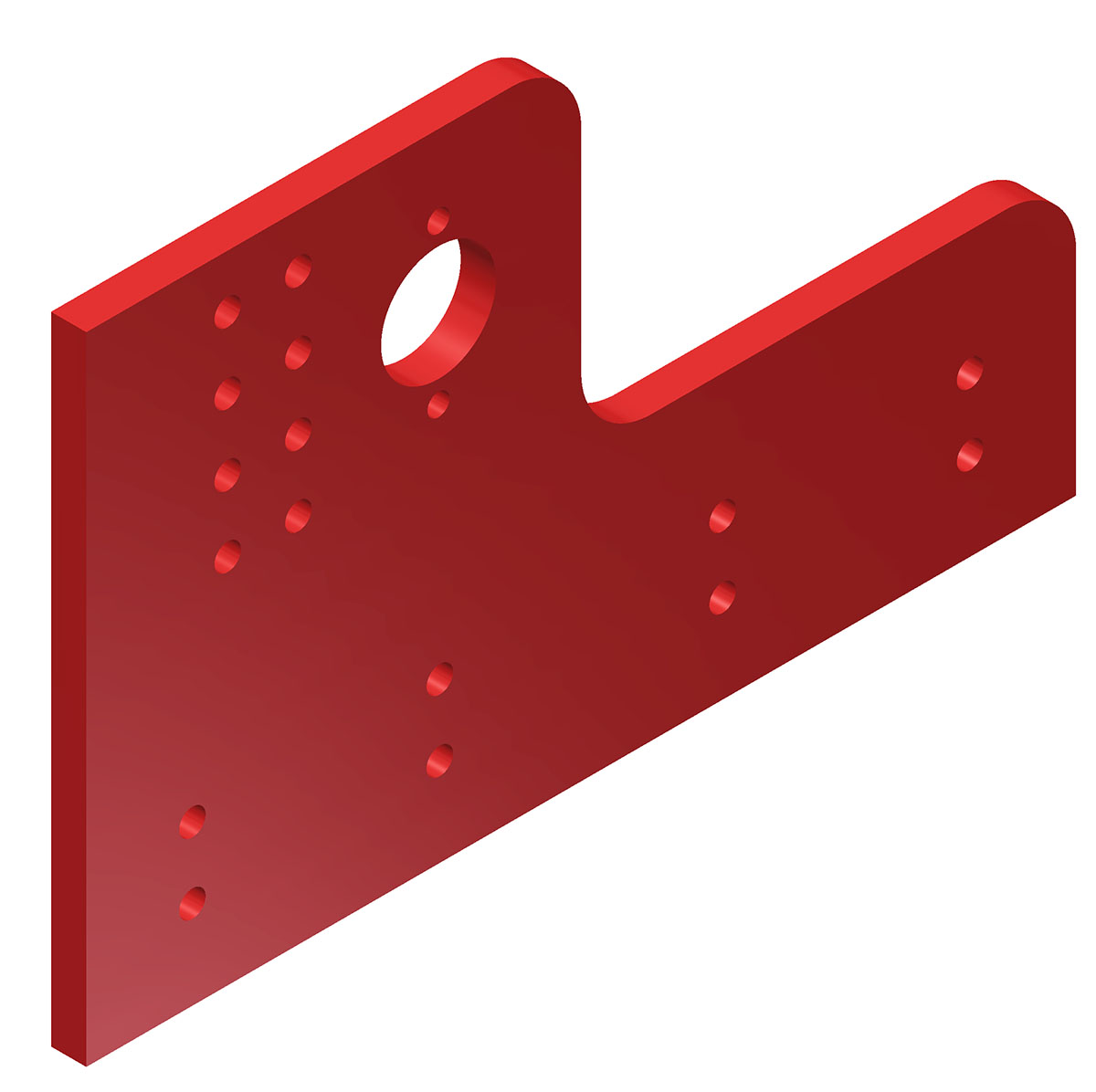

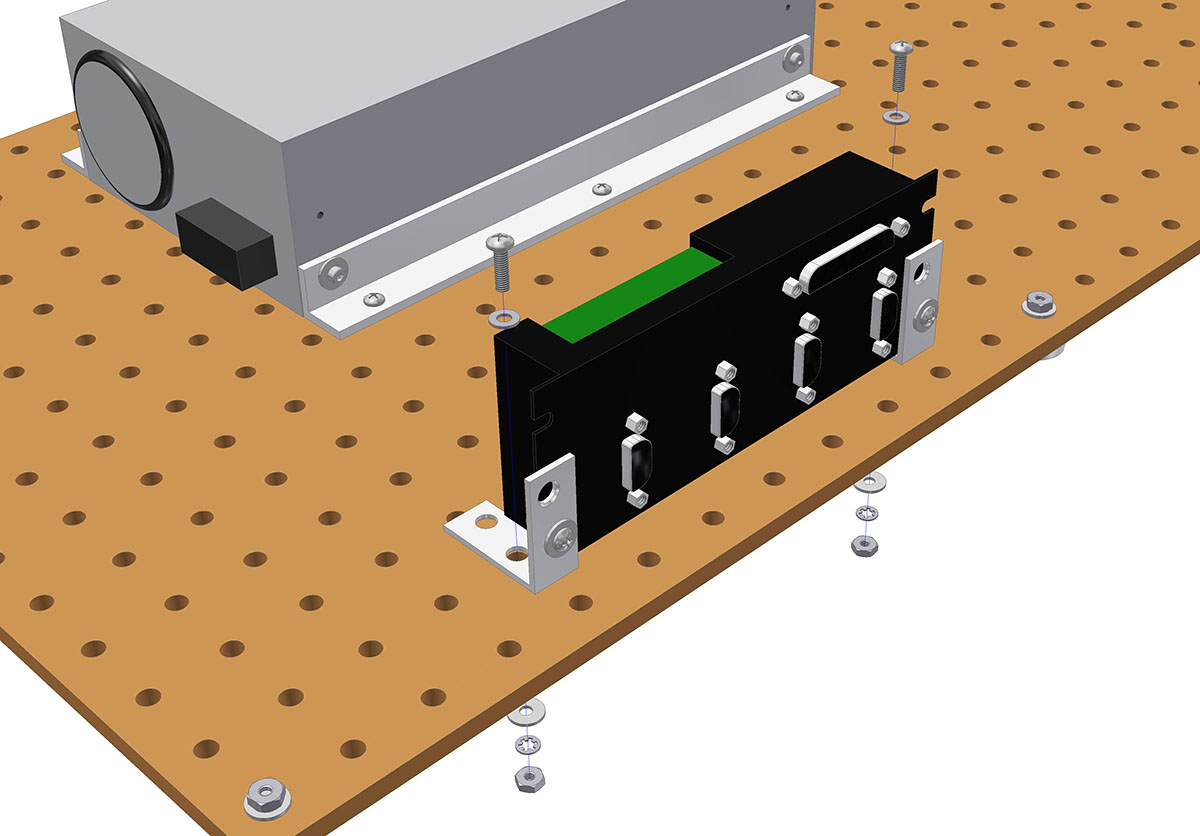

The CNC Construction Set features a removable Z-carriage. This allows for Z-carriages that are better designed to suit the type of operation you are performing. In addition the Z-Plate is also replaceable making it even easier to change operations.

The following is a list of the currently available workbooks. Each volume includes its own detailed “Bill of Materials”, with product links to the components needed for the frame construction.

Note that these are available as digital downloads only. They are in gray scale PDF form so they are ready to print if you so desire.

Volume 1

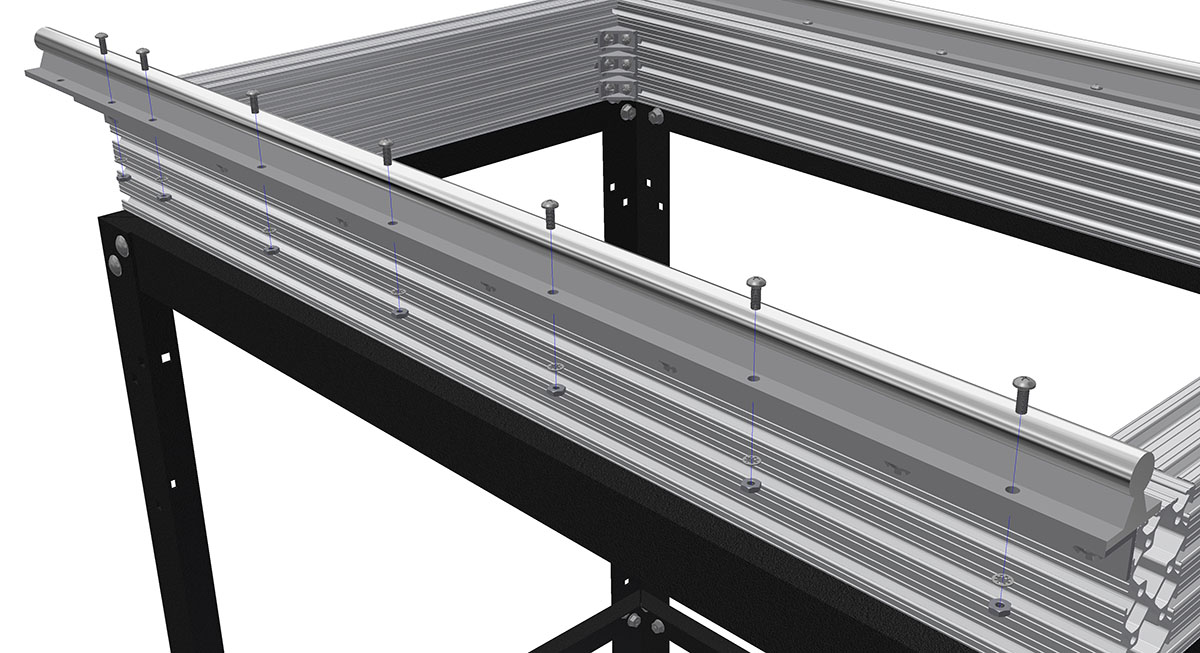

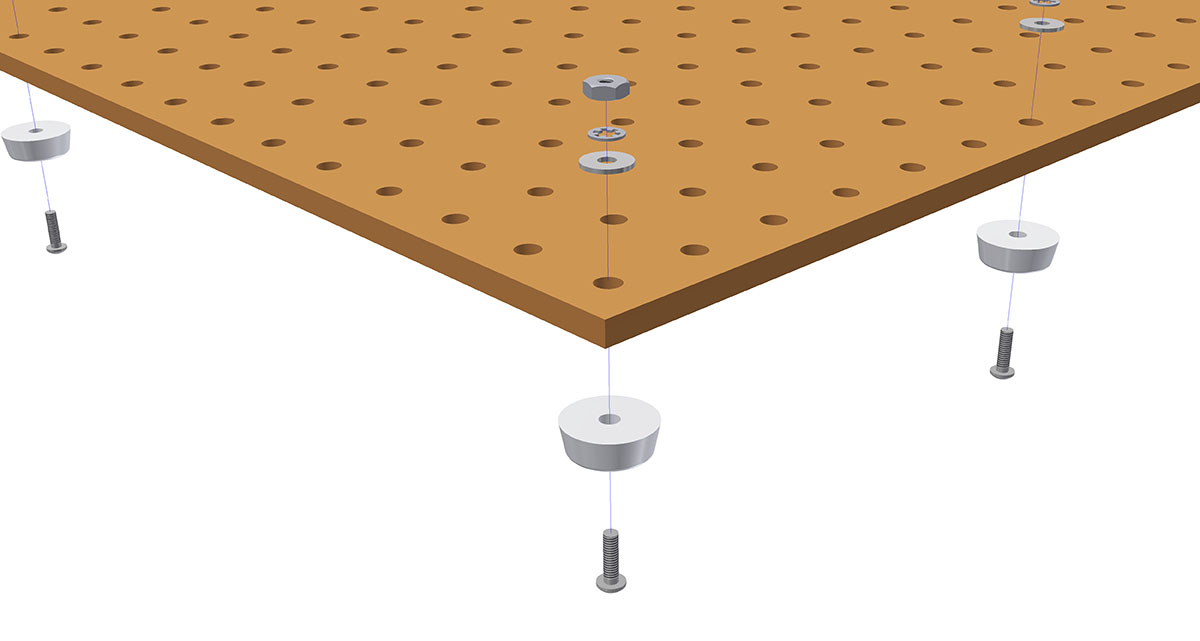

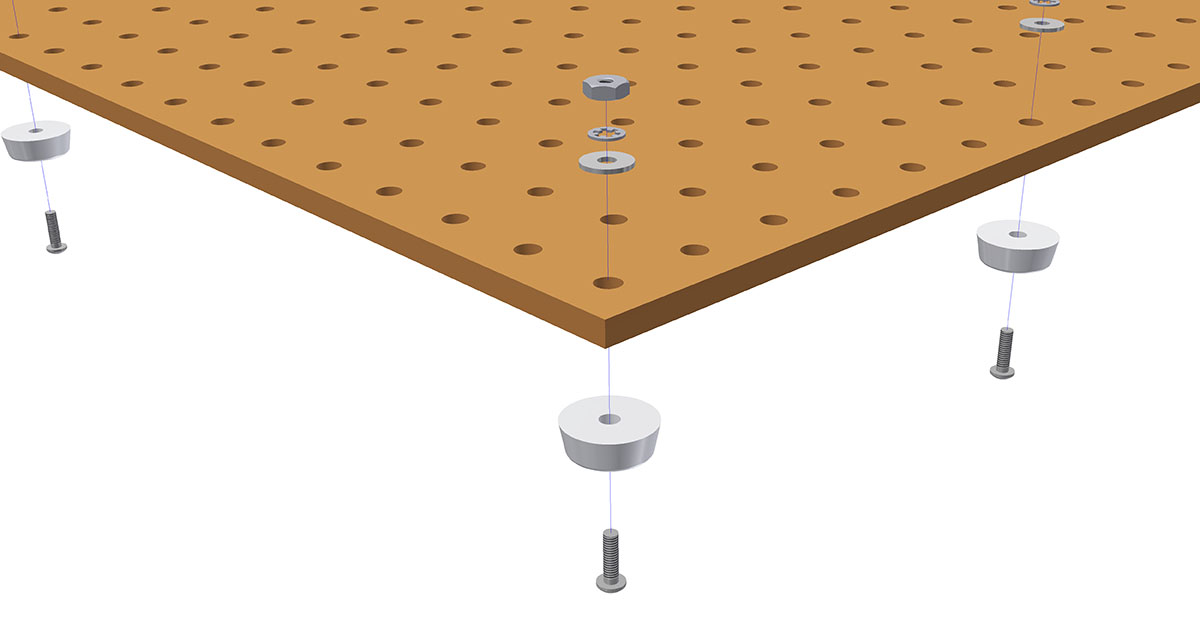

CNC Construction Set Volume 1 : Frame and Carriages

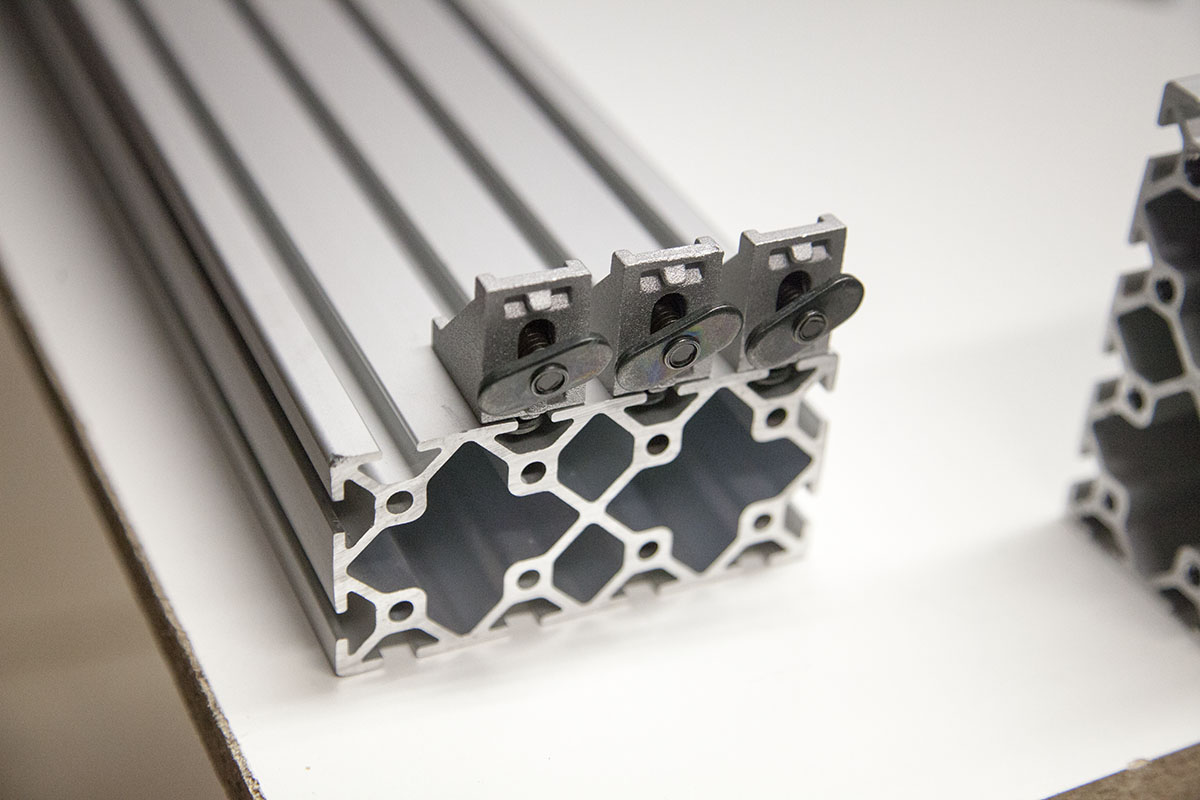

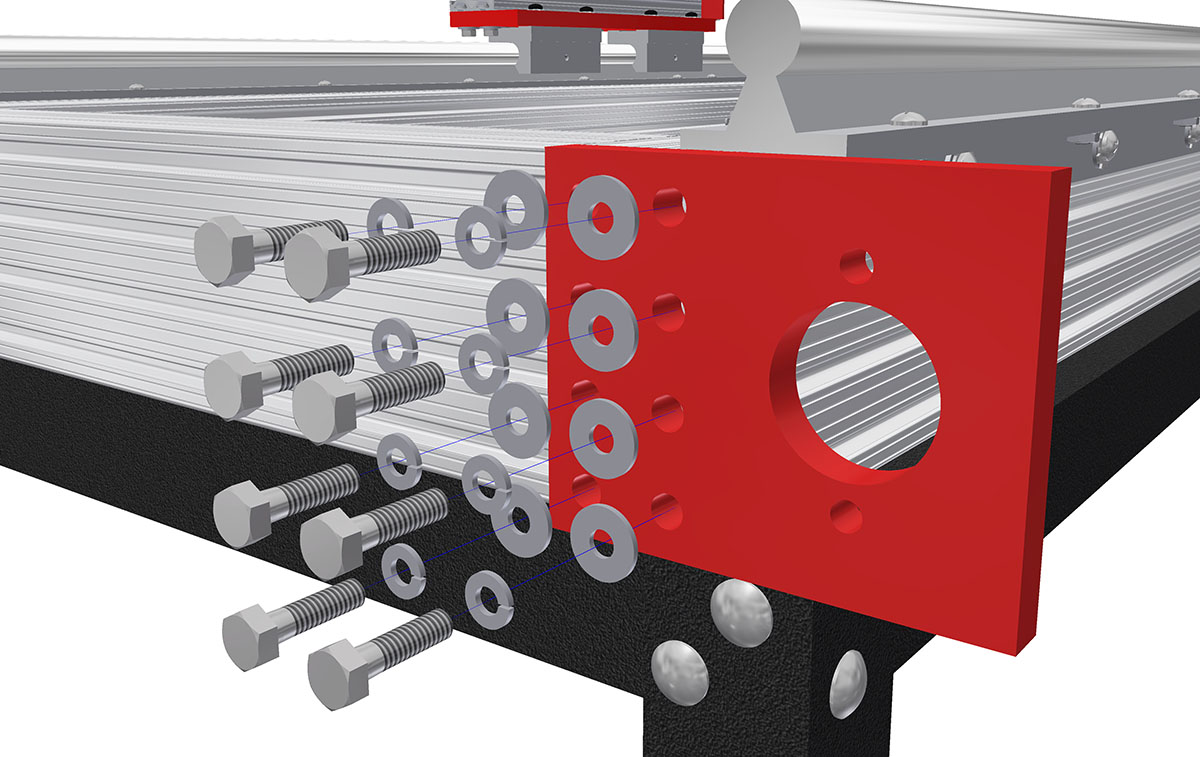

Volume 1 is the foundation to the CNC Construction Set. It covers the basic frame and carriage construction.

Pages 112

Chapters 11

Get volume 1 here: Volume 1

Volume 2

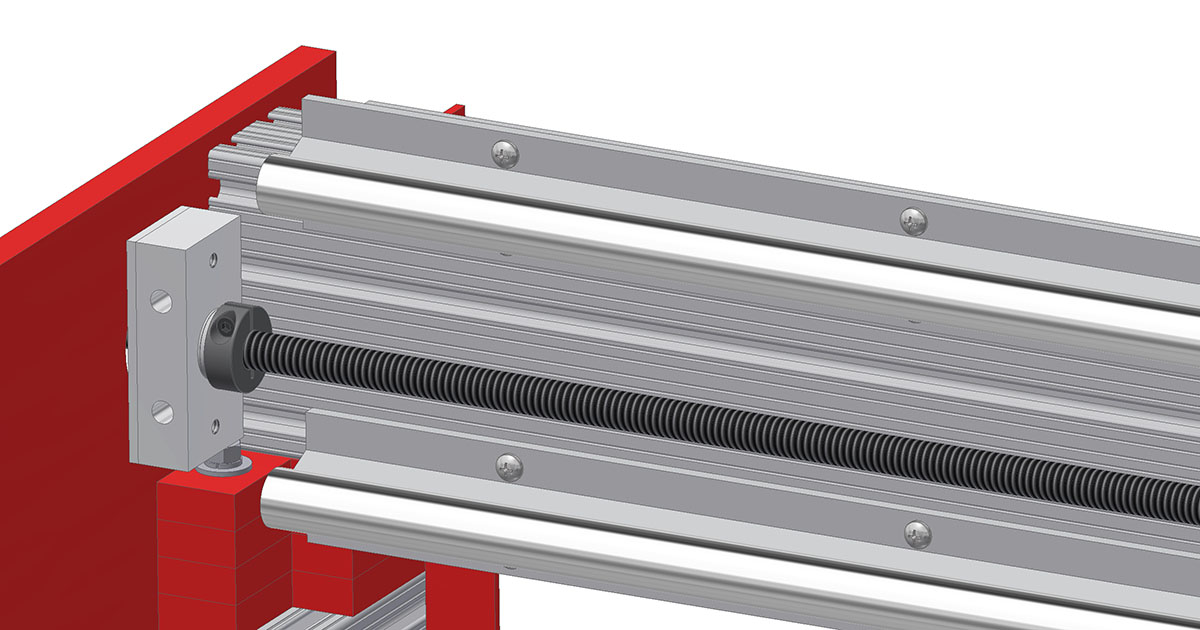

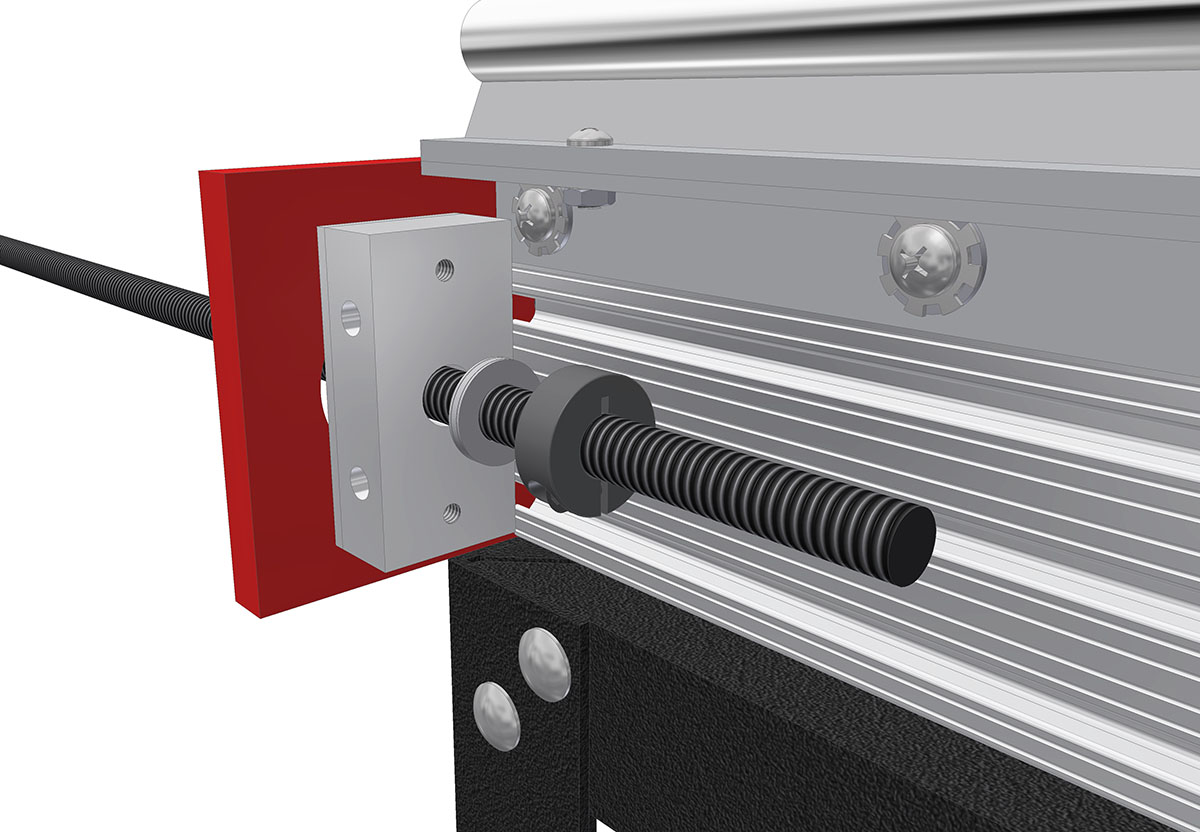

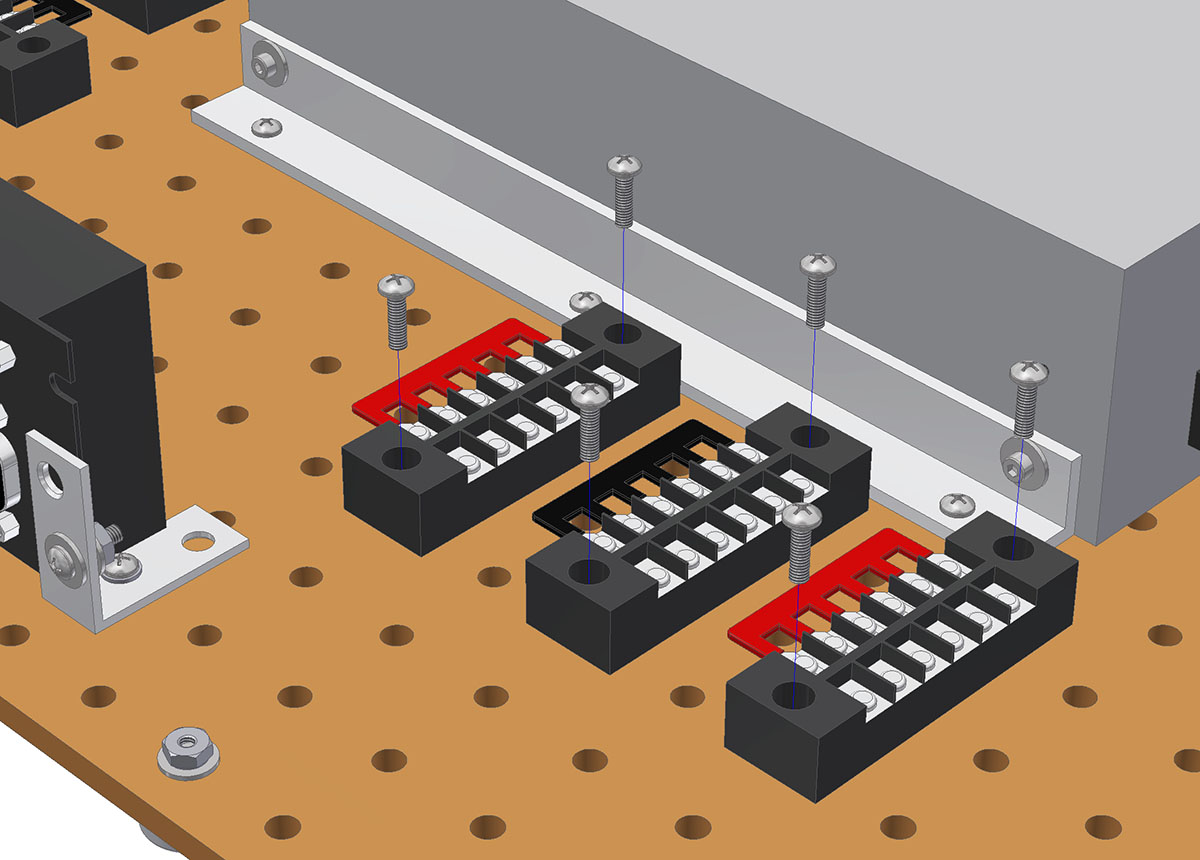

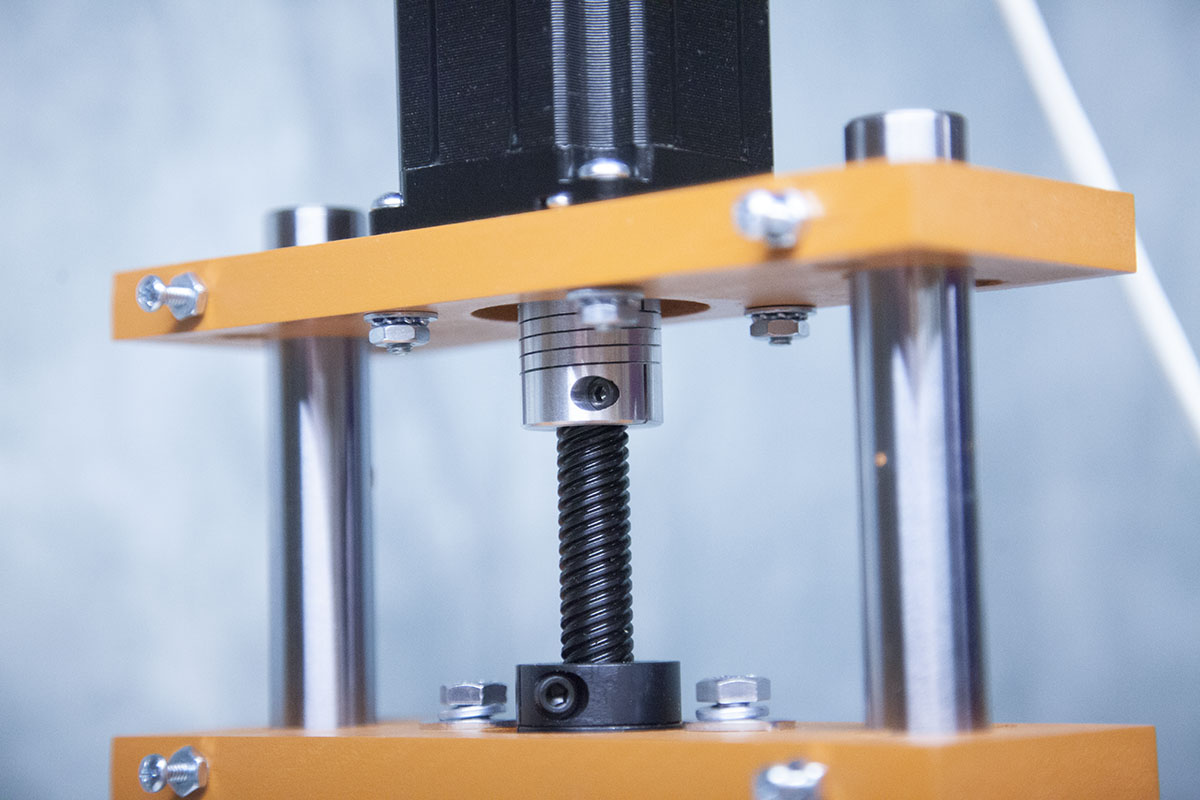

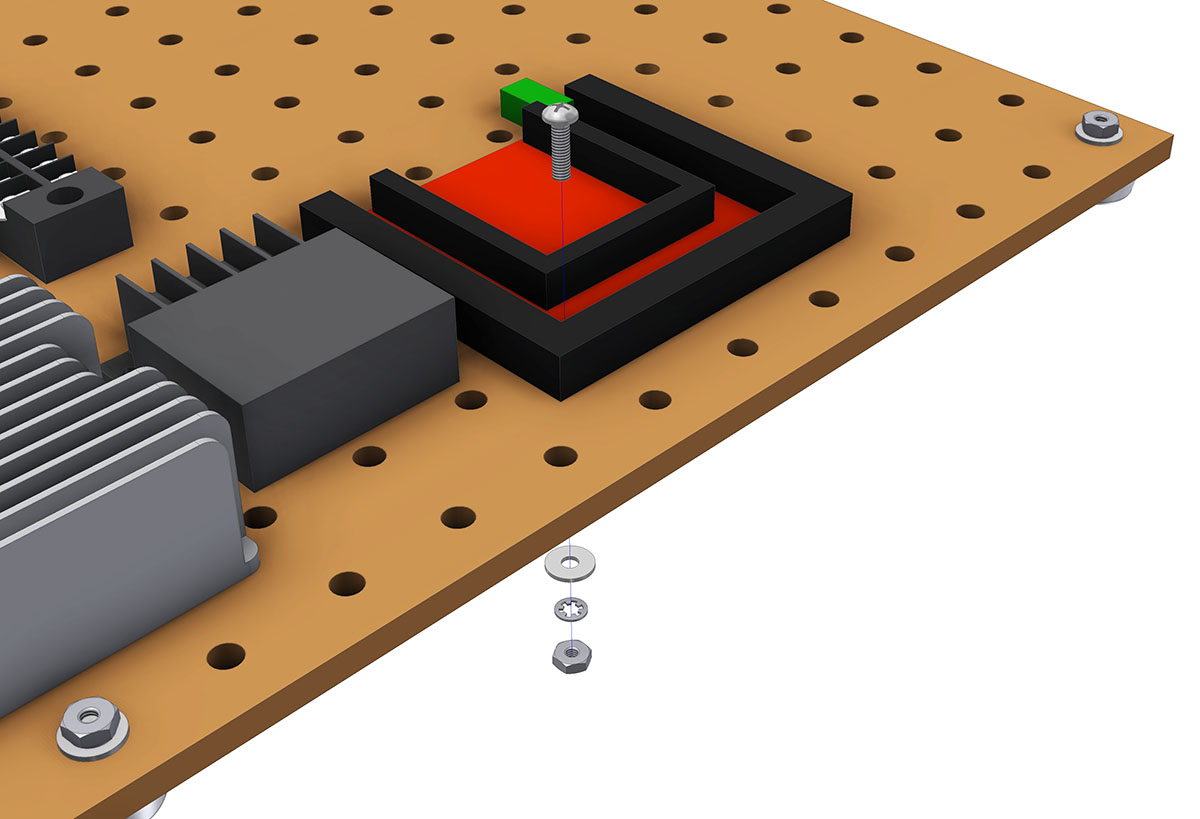

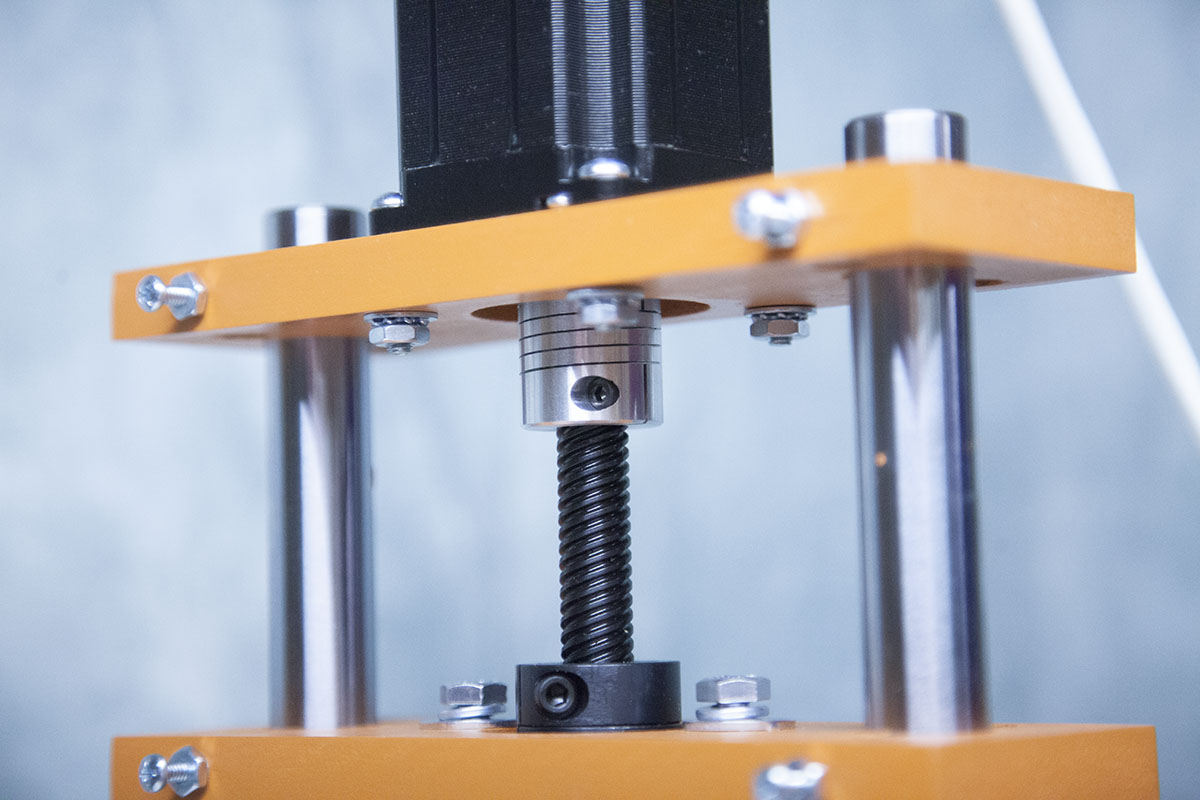

CNC Construction Set Volume 2: ACME Drive Components

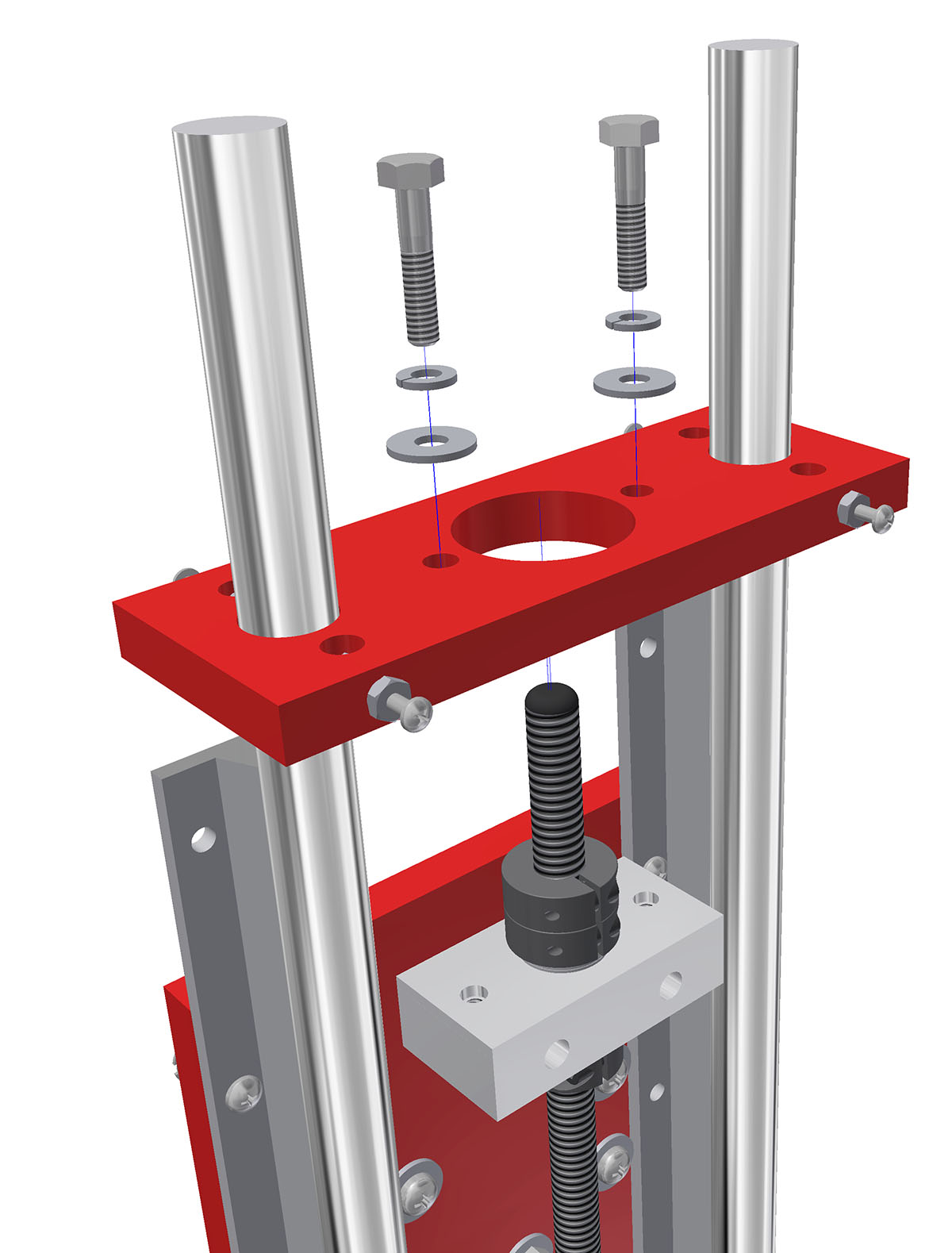

Volume 2 covers the ACME screw drive components and installation. In addition you will be shown how to do some extensive tuning of the carriages.

Pages: 170

Chapters: 15

Requirements: Volumes 1

Get volume 2 here: Volume 2

Volume 3

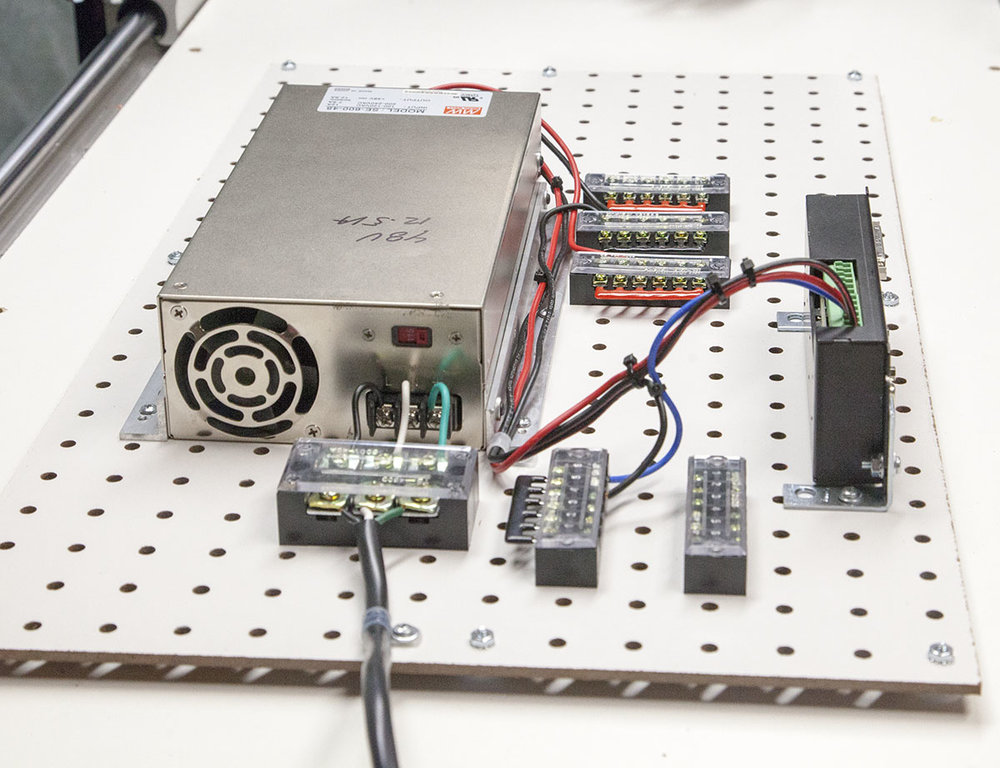

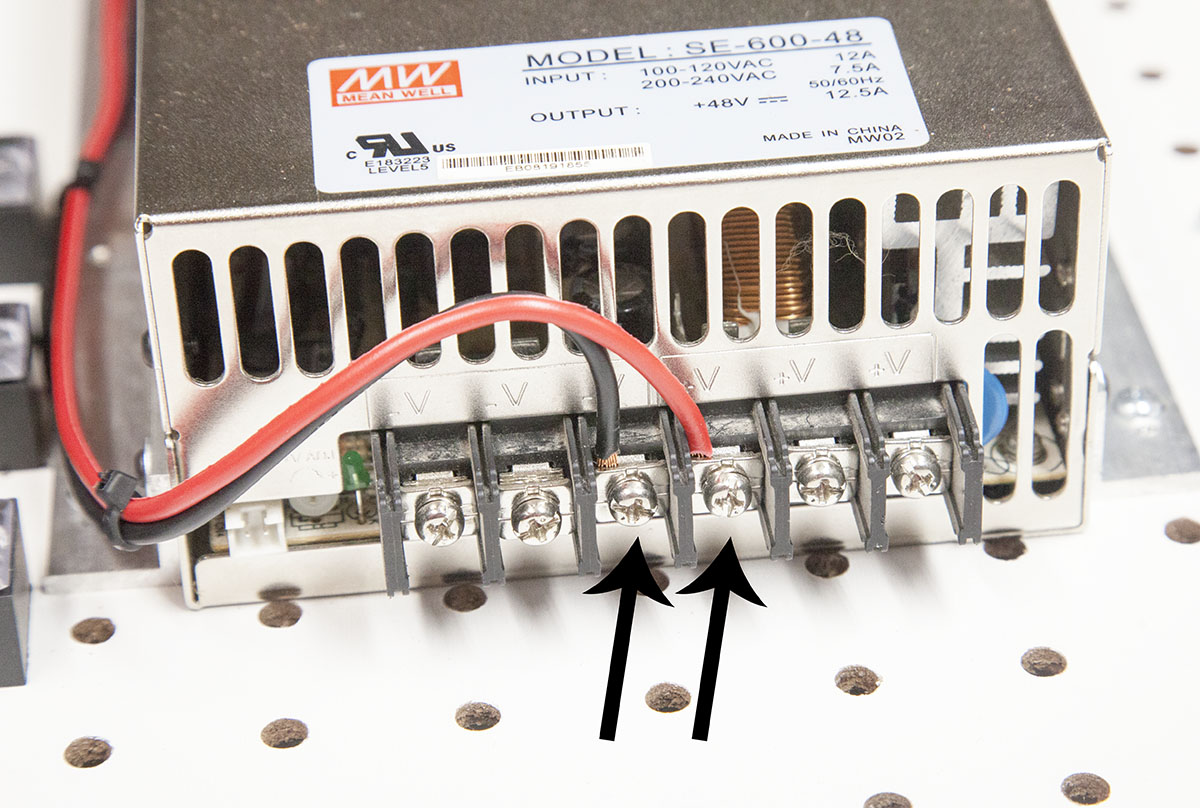

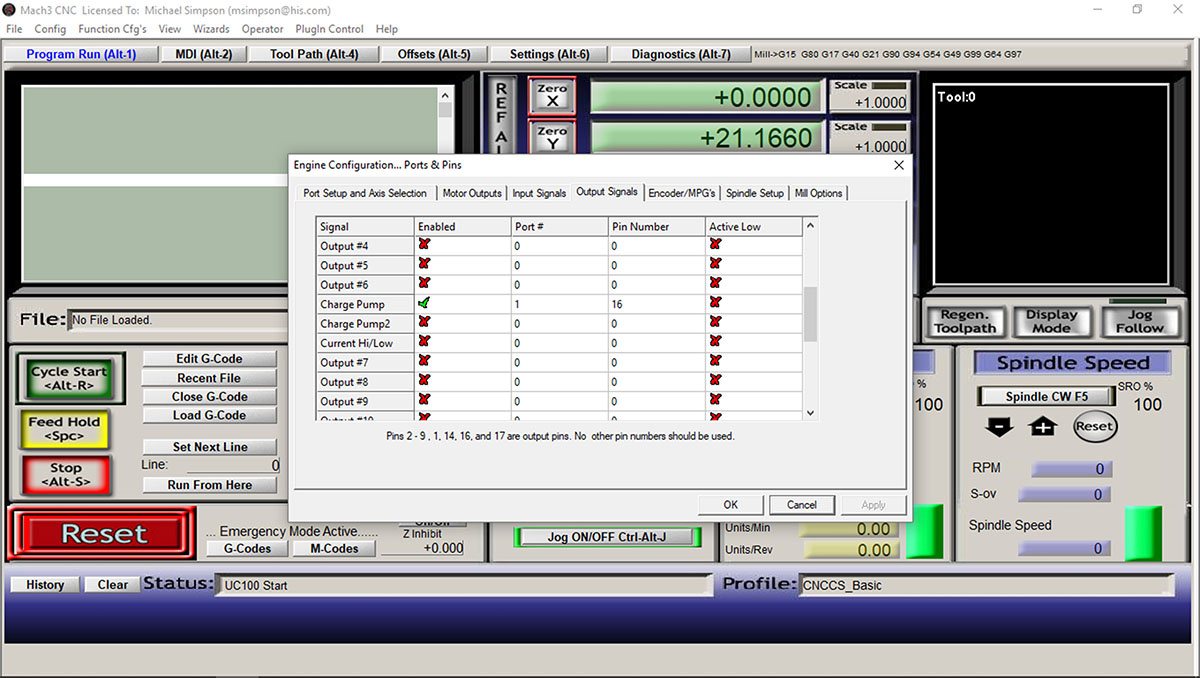

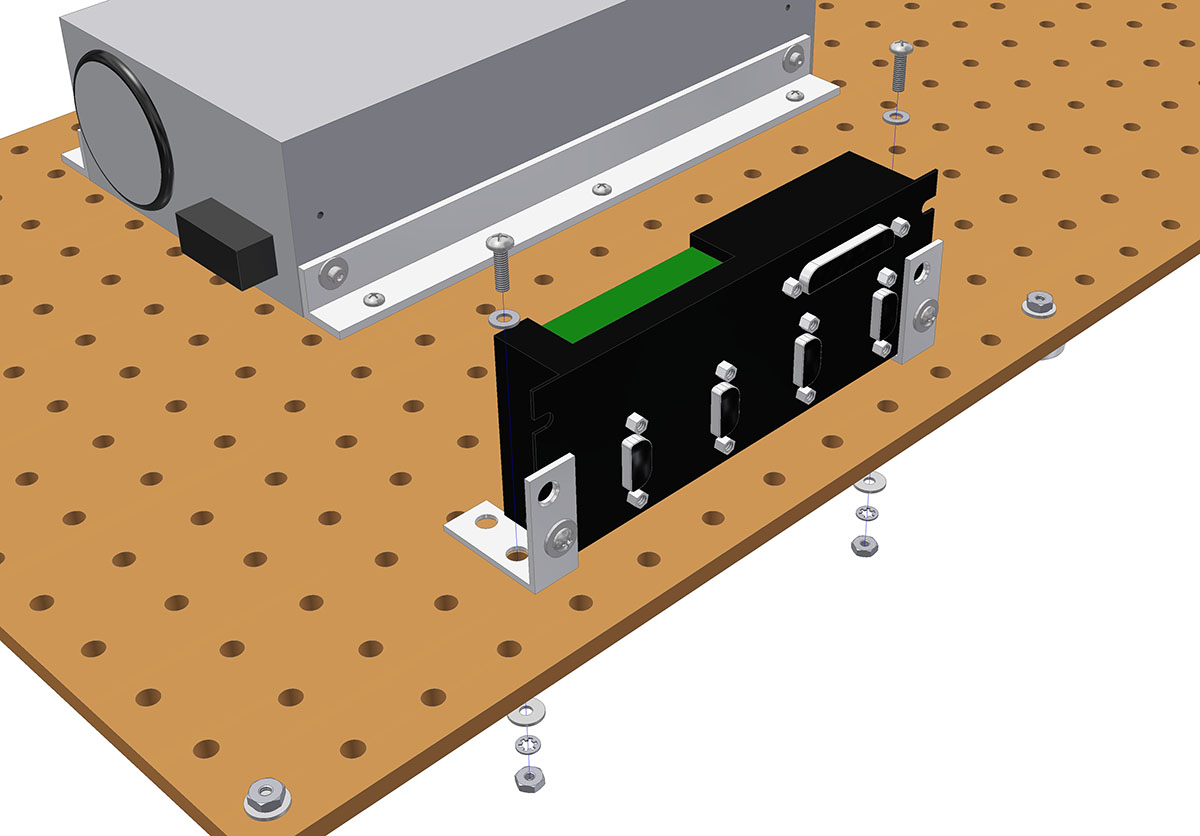

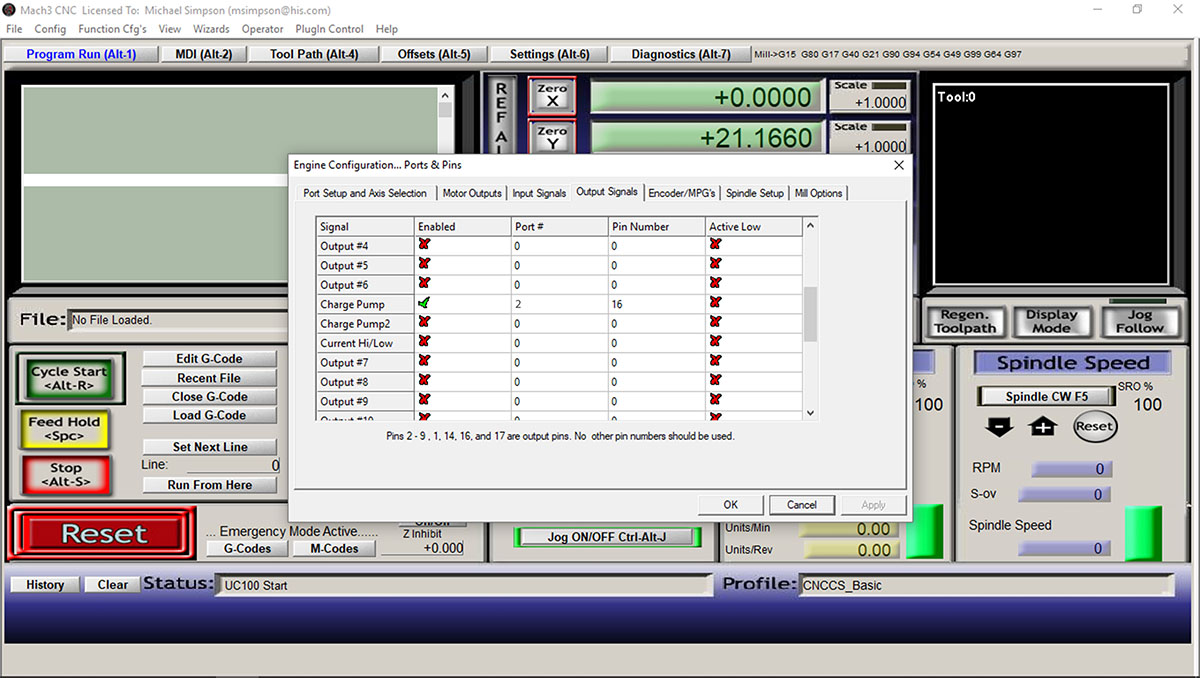

CNC Construction Set Volume 3: Basic Electrics

Volume 3 covers the hookup and configuration of the steppers motors using the UC100 motion controller, G540 and Mach3.

Pages: 160

Chapters: 14

Requirements: Volumes 1 and 2

Get Volume 3 here: Volume 3

You must choose between basic electrical hookup (Volume 3) or advanced electrical hookup (Volume 3B).

The UC100 is great for 3 axis milling. It will allow you control your machines 4 stepper motors. The UC100 is the most inexpensive way to get your machine moving.

Volume 3B

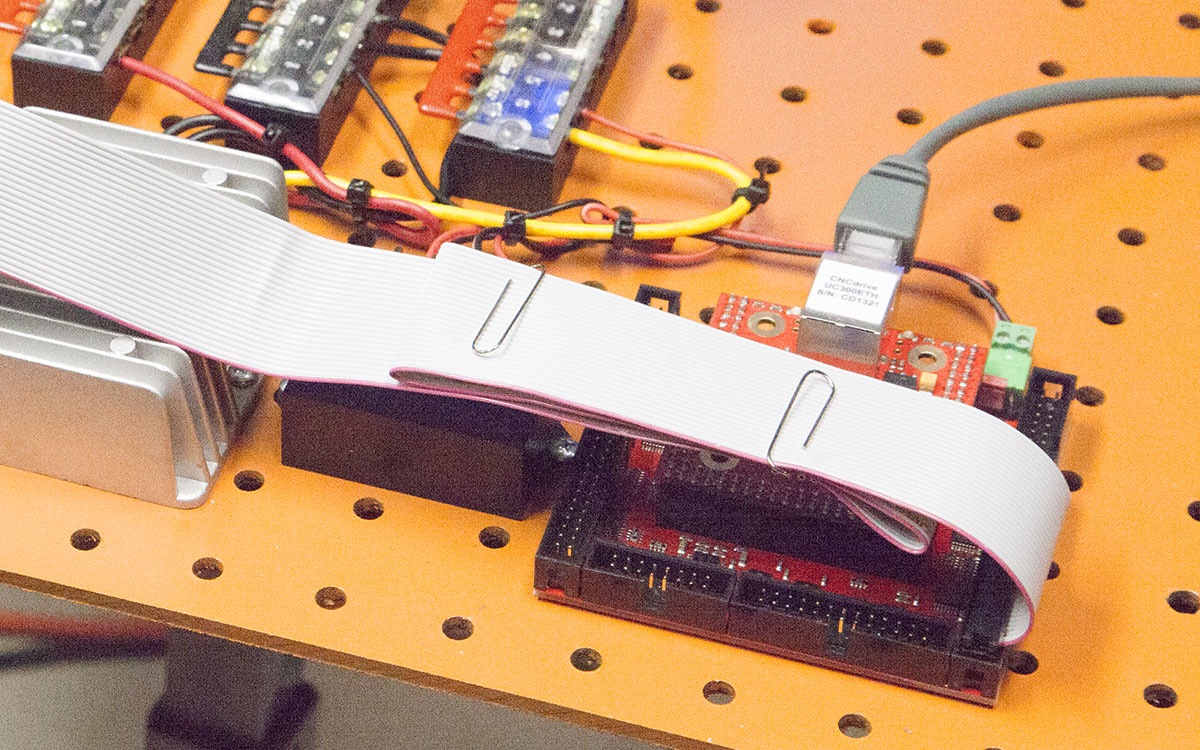

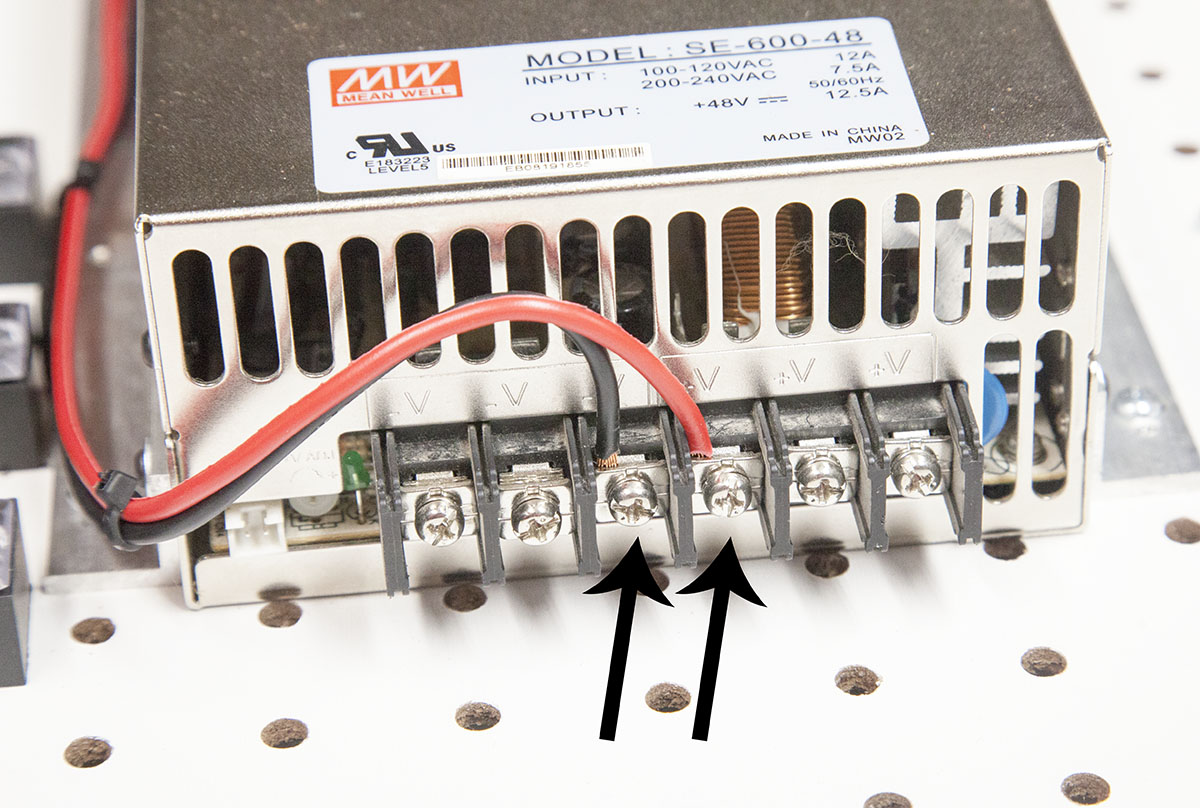

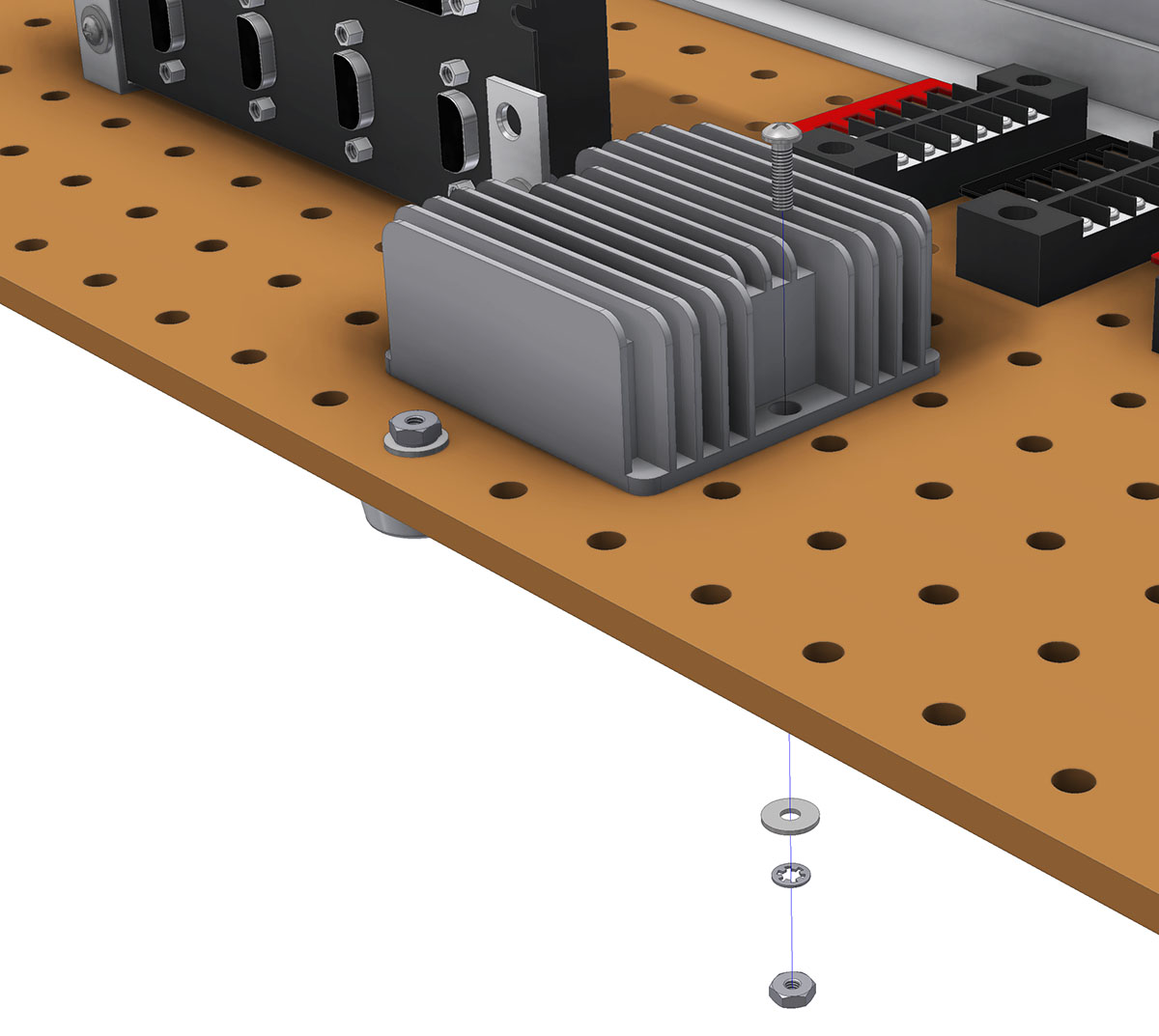

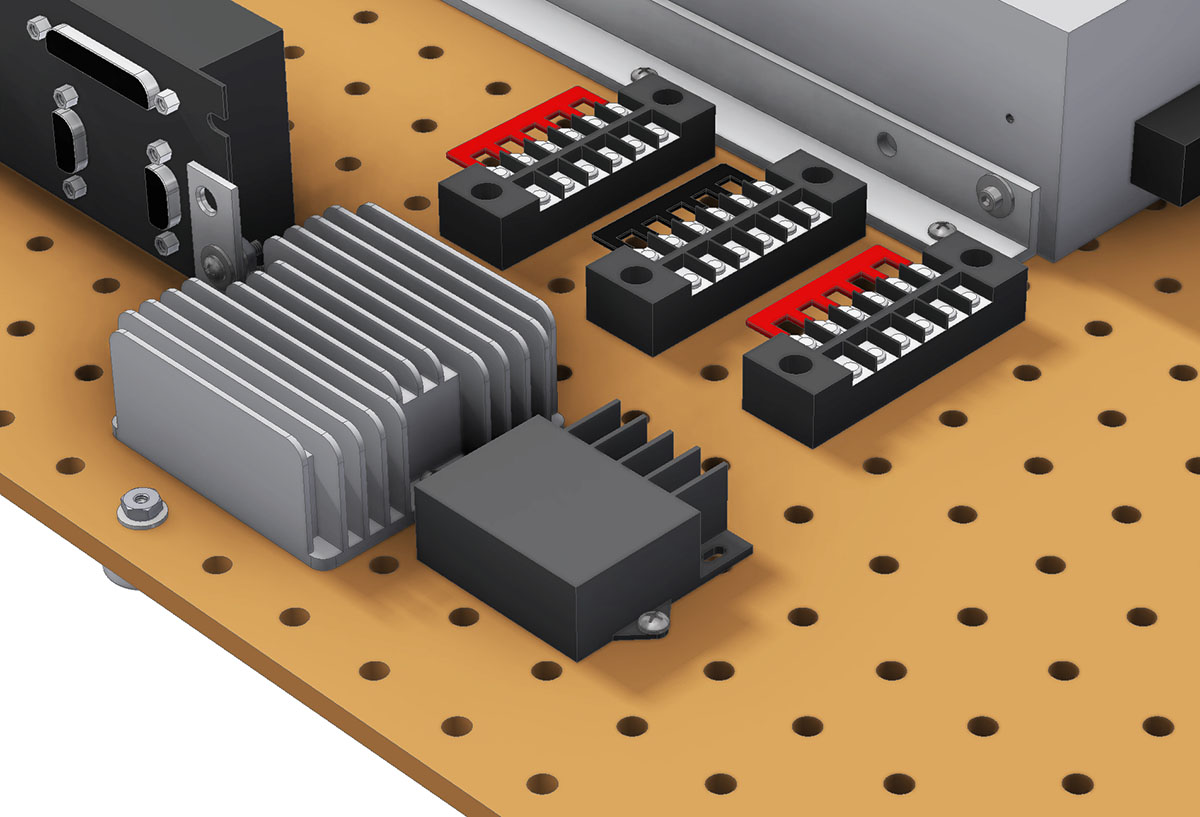

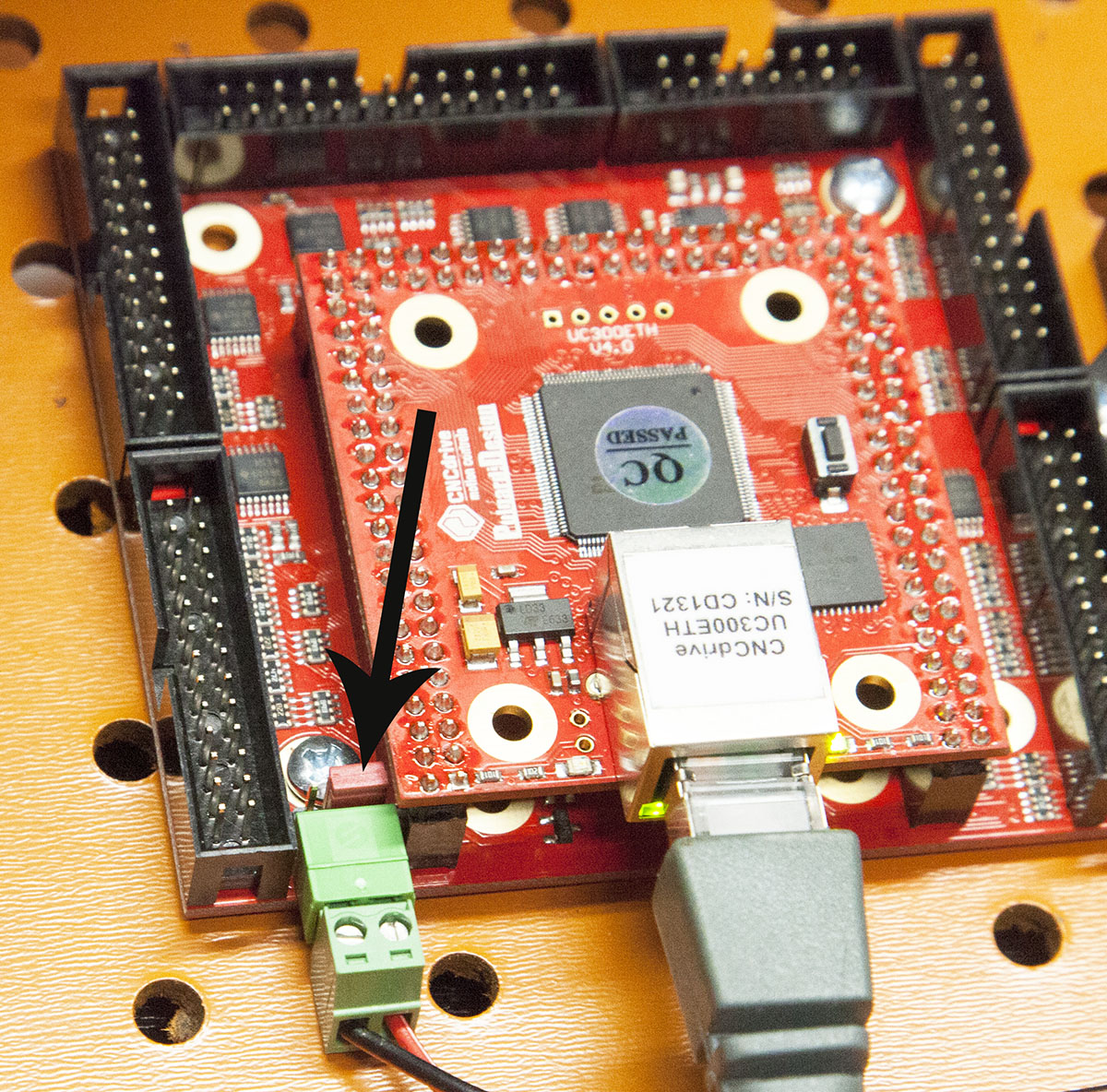

CNC Construction Set Volume 3B: Advanced Electrics

Volume 3B covers the hookup and configuration of the stepper motors using the UC300ETH motion controller, G540, and Mach3. This volume also covers adding both a 12V and 5V regulator for various accessories and breakout boards.

Pages: 194

Chapters: 18

Requirements: Volumes 1 and 2

Get volume 3B here: Volume 3B

The UC300ETH is a more advanced controller that will enable you to add more control of your machine. You will be able to add several more motors to your machine for some very complex operations.

While the UC300ETH will cost you more to get up and running, is is better suited for operations like plasma cutting.

Volume 4

Reserved for future use

Volume 5

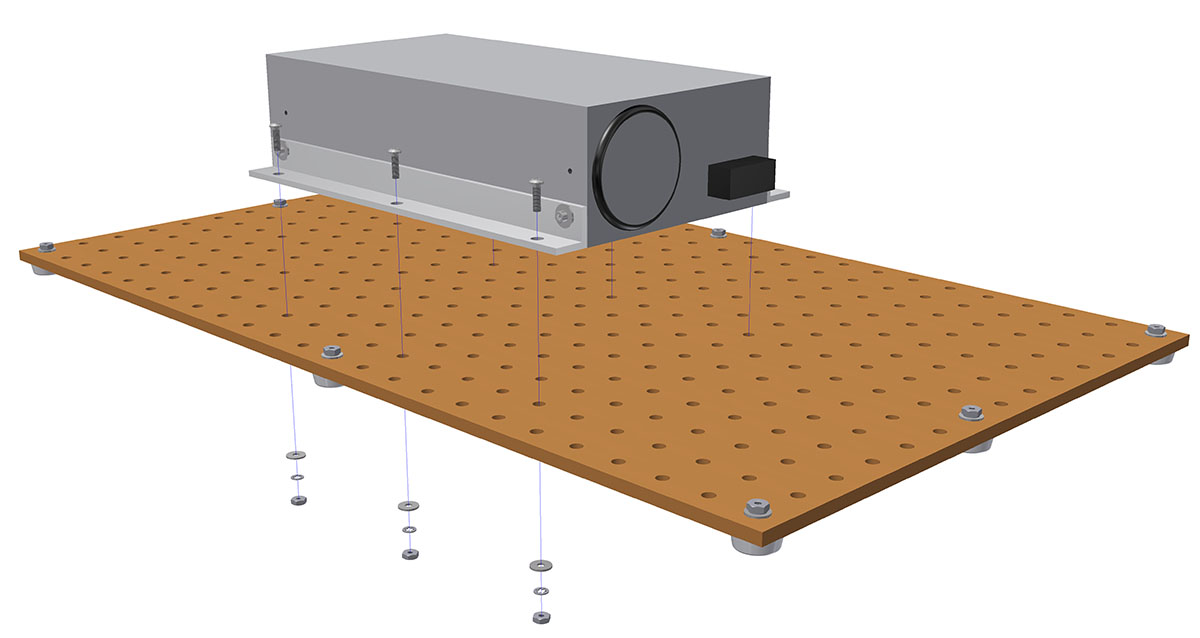

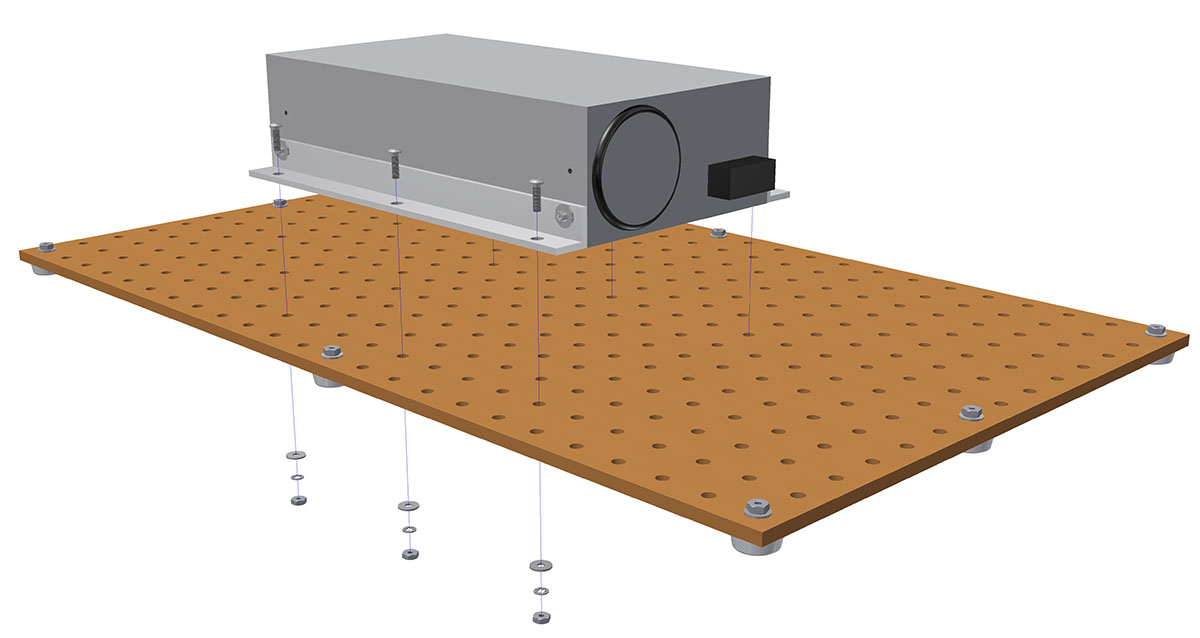

CNC Plasma Table - Everlast Edition

Volume 5 covers adding a plasma table and downdraft system to your machine using an Everlast 50s plasma cutter.

Pages: 174

Chapters: 16

Requirements: Volumes 1, 2, and 3B

Get volume 5 here: Volume 5

Most of the plasma upgrades and articles will take place in the plasma area located here:

Volume 5B

CNC Plasma Table - Hyperterm Edition

Volume 5B covers adding a plasma table and downdraft system to your machine using a Hypertherm PM65.

Pages: 168

Chapters: 16

Requirements: Volumes 1, 2, and 3B

Get Volume 5B here: Volume 5B

Most of the plasma upgrades and articles will take place in the plasma area located here:

Volume 6

Heavy Duty Floating Head

Volume 6 covers adding a heavy duty floating head to your plasma build.

Pages: 158

Chapters: 16

Requirements: Volumes 1, 2, 3B, and 5 or 5B

Get Volume 6 here: Volume 6