There is not much you need to do in order to make PCB boards using your CNC machine.

It's assumed that your machine has been tuned and calibrated. A inch square created in your CAD/CAM software should mill an inch square on your machine.

It's also assumed that you have installed fences at your zero reference for both the X and Y. I also recommend homing switches on the X and Y axis that refference 0,0 to the inside edge where the two fences meet.

Is it Square

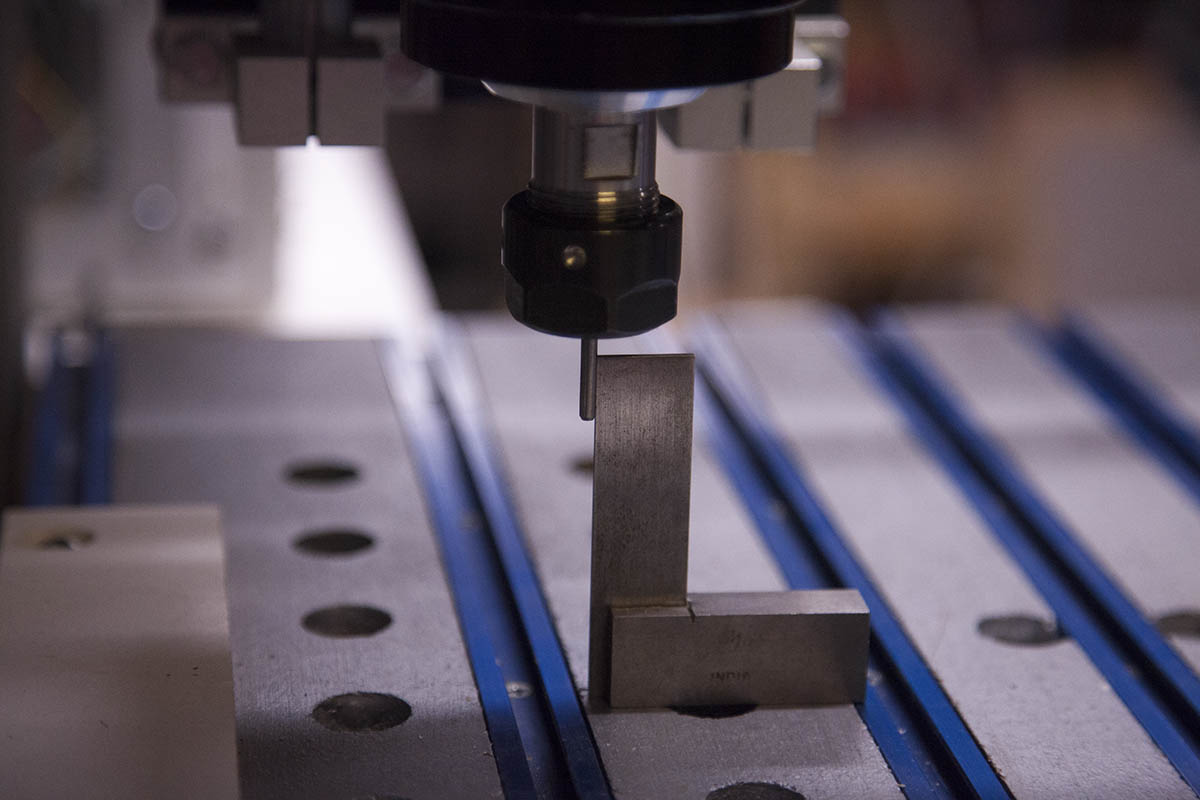

The first thing you want to do is to make sure your spindle is square to the table surface Do this by inserting a calibration bit and checking with a small square, as shown here.

If you dont have a calibration bit, you can use a straight bit.

If the spindle is not square to the table, you need to correct this before continuing.

On this particular machine (Titan), I have just added this water cooled spindle. This is much heaver than the router the machine was designed for so I had the shim the two adapters I made in order to use an existing. The spindle can be out of square and you can still make great PCB boards, but the surface you will be milling into the fixture could be compromised.

Set Y-axis Fence

Home your machine then move the Y-axis to .0625. This is half the diameter of the bit, which in my case is 1/8" in diameter.

This will put the edge of the bit at 0.

Move the X axis over to about 1" and slowly lower the bit. The edge of the tool should touch the edge of the fence. If it does not, loosen the fence screws and push it against the bit. Snug the screw.

Move to the other end of the fence and do the same thing. Go back and forth a few times and when you are confident the fence is correctly positioned, tighten the screws.

Set X-axis Fence

Home your machine then move the X-axis to .0625. This is half the diameter of the bit, which in my case is 1/8" in diameter.

This will put the edge of the bit at 0.

Move the Y axis up to about 1" and slowly lower the bit. The edge of the tool should touch the edge of the fence. If it does not, loosen the fence screws and push it against the bit. Snug the screw.

Move to the other end of the fence and do the same thing. Go back and forth a few times and when you are confident the fence is correctly positioned, tighten the screws.

While you can mill the PCB without fences, they make setting up your fixture much easier.