I use my 3-in-1 press/break/roller for a lot of projects. As long as you stick to the 20 gauge or less limitations, it works very well

These are sold by a number of companies and even on Amazon.

This one is a 30” Central Machinery beast, but you can get them in 8”, 12”, 30”, and 40” versions.

Built-in Stops

Mine came with this adjustable stop on the back of the machine.

It can even be used to help support longer stock when using the press break.

The problem with using these stops, is that they are a pain to get setup for real accurate cuts or bends. The also wont work for cutting or bending smaller pieces. I almost never use them.

Aligning Layout Lines

The method I use most is to place a line on the part and use that to help me align the part to be cut or bent.

For shearing it’s simple enough to place a line on the part to be cut and align the ends with the edge of the cutter, as shown here.

For bending this is much harder, and is very hard to achieve any kind of accuracy.

Guides

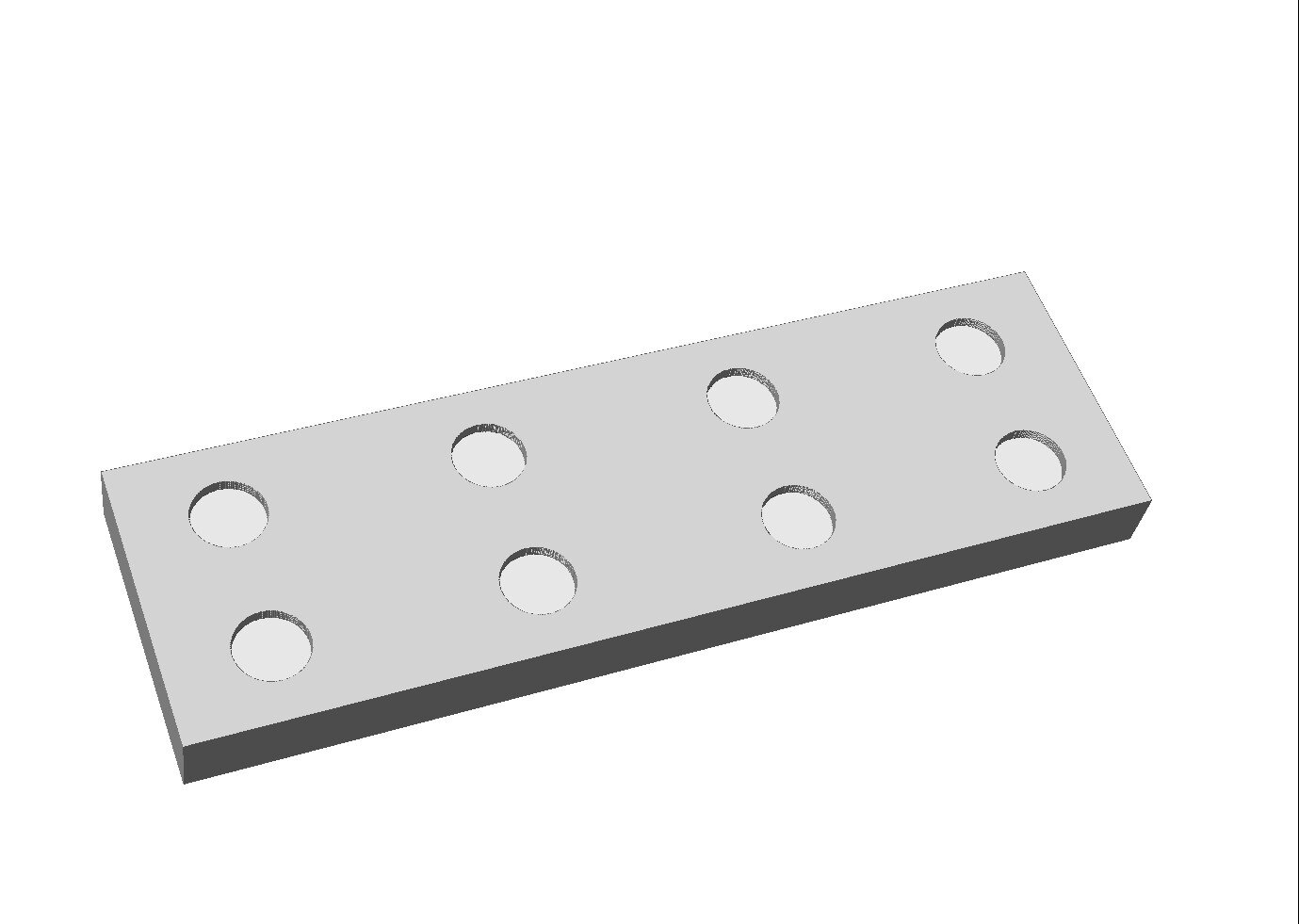

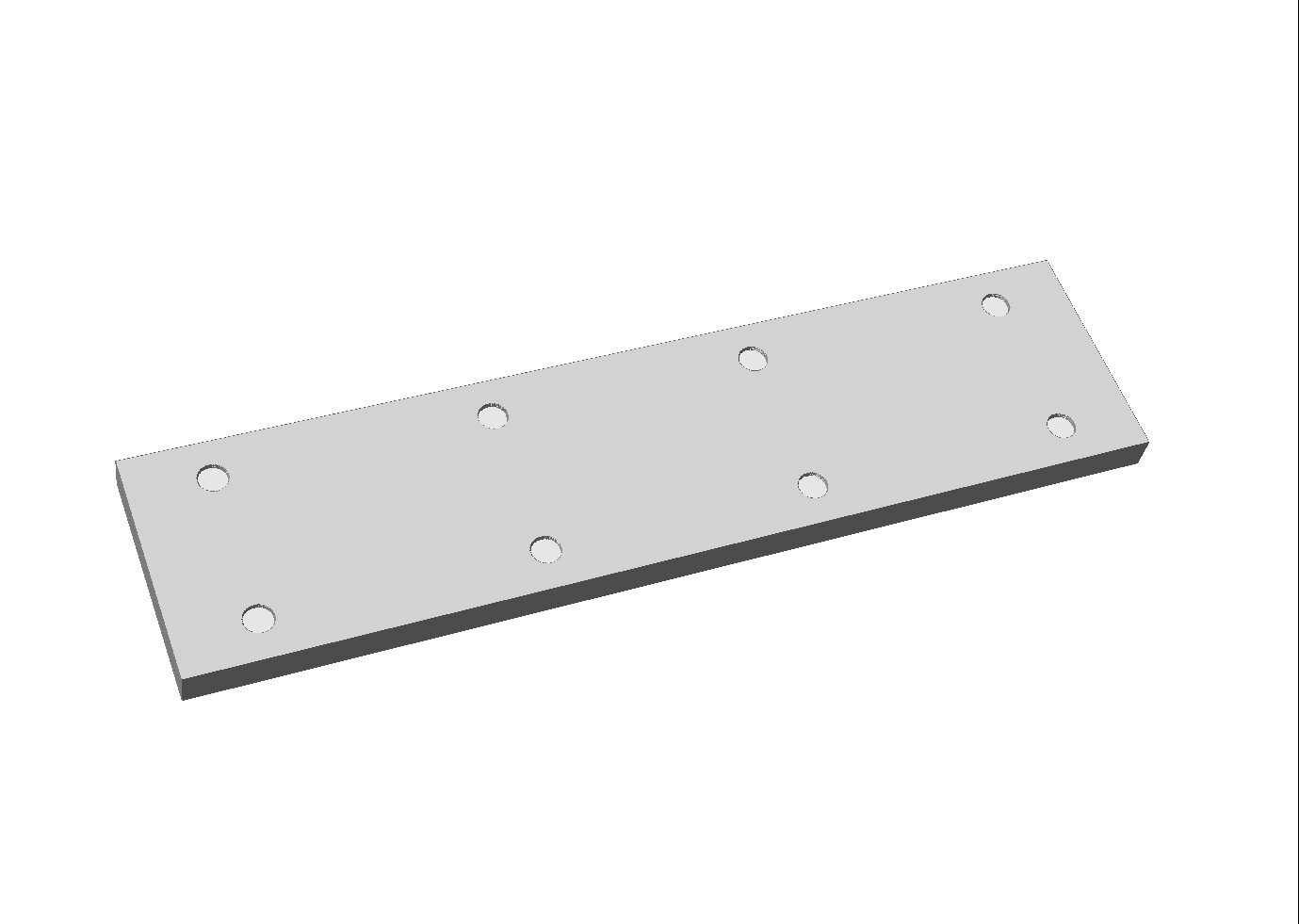

These are a set of guides I made to help me align the stock while I am bending or cutting it.

They were made by milling some pockets in some 1/2” or 3/8” stock.

The pockets hold a magnet flush with the surface. The pockets are a couple thousands shy of the diameter of the magnets so they can be press fit into place.

The stock is PVC with the smaller one 5” x 1-1/2”, and the larger one 12-1/2” x 3”.

Note that other materials will work for the guide, but you may have to experiment with the diameter of the pocket to get a good fit for the magnet you choose.

Using the Guides

For shearing, I mark a line where I want the stock to be cut.

I then place the guide on the stock with the edge on the line.

The stock is placed on the shear, with the edge of the stock pressed against the cutter.

Once in-place the part is cut. It works very well and is more accurate than trying to align the line to the edge of the cutter.

For bending, I place a mark where I want the bend to be.

I then place a second line 1/8” from the bend line, as shown here.

The guide is placed on this second line. In other words, the stock is placed 1/8” from the bend line.

The stock is placed on the break with the guide up against the fingers, as shown here.

The part is bent. Note that you may want to remove the guide about 1/2 way through the bend.

Very accurate and consistent bends.

Other Tips and Tricks

I take a piece of scrap 2” steel angle and add some magnets.

I then stick the magnets against the sheer blade, flush with the top of the break base, as shown here.

This provides you with a shelf to help support the stock.

Here I take an old magnetic base for an old dial indicator and attach some magnets the side.

To these magnets a place a piece of scrap bar stock. This guide can be squared against the cutter, thus providing an accurate fence.